ITRS 2025 Presentation: Testing Old and Unused Rope

Introduction:

Each year, the International Technical Rescue Symposium (ITRS) brings together professionals from across the rescue industry to share research, insights, and expertise on a wide range of topics. These discussions cover everything from advanced rope systems to innovative techniques and emerging technologies that help shape the future of rescue operations. This year, two of our CMC school instructors. John McKently and LeRoy Harbach, attended and presented at ITRS 2025. Their session focused on testing old and unused rope, offering valuable findings and practical implications for the field. Explore their research and testing papers below, as presented at ITRS.

About the Authors

John McKently – John has nearly 50 years of search-and-rescue experience, including 47 years with the Los Angeles County Sheriff’s Department and 35 years as an instructor for California OES. A former School Director at CMC, he continues to teach advanced rescue courses such as Rope Rescue Technician and Confined Space Rescue.

LeRoy Harbach – Retired with a total of 27.5 years in the fire service, LeRoy served 18.5 years with the Caledonia (WI) Fire Department and 9 years with the City of Waukesha Fire Department. LeRoy is an instructor for the following CMC classes: Rope Rescue Technician I/II/II; Confined Space Rescue Technician; Tower Rescue; Rescue from Heights; Rescue for Stage Riggers; Rescue from Fall Protection; Industrial Rescue.

About ITRS

CMC takes pride in co-founding and co-sponsoring the International Technical Rescue Symposium (ITRS), an annual gathering that brings together a diverse array of professionals in the technical rescue field. This includes experts in fire, mountain, cave, urban, industrial, and swift water rescue. At the symposium, presenters willingly share their research findings, testing outcomes, and field experiences for the collective benefit, encouraging attendees to reflect on and implement these insights. The symposium’s scale provides an ideal setting for extensive discussions and the exchange of knowledge.

Testing of aged and in some cases antediluvian diamines and dicarboxylic acid AKA: 2 old guys testing old stuff.

By John McKently and Leroy Harbach

Introduction

With the potential upcoming changes to NFPA 2500, we decided to accumulate old unused rope, webbing, harnesses, and anything else we could find so see if any strength degradation had taken place. We tested unused (fresh from the spool) 7/16th (11mm) rope, 1/2” (12.5mm) rope, 5 mm technora rope, with an age range of 14-21 years old. We also tested lightly used 10-year-old webbing and unused 1” webbing 22 years old, along with unused 2” 12-year-old web.

Testing

For the past several years we have presented papers on knot efficiency using various rope sizes, materials and constructions. Our testing results were often different-sometimes higher, sometimes lower, than the numbers given in several rope rescue manuals. There are valid reasons for the differences between our testing and those of the past including: standardized test methods, improved instrumentation and changes to rope materials and construction. Based upon our testing we suggest that you consider using a lower knot efficiency when doing system safety factor calculations. Instead of the old 75-80% average it is probably safer to use 50% for all knots.

While conducting the knot testing our results were often very different than the previously published numbers. We questioned the validity of the published strength loss in older software-rope, webbing, anchor straps, harnesses and other components in rescue systems. Where did the numbers come from and were they based upon valid testing?

In 1967 Walt Wheelock in Ropes, Knots and Slings for Climbers stated that “Tests have proven that a nylon rope may lose 20% of its overall strength with 100 days of use.” Unfortunately, no details were given about those tests.

One early study was by Bruce Smith (Nylon Highway #25-1988) on new, used and abused ropes. The report has percentage loss numbers for several brands of rope with the conclusion that rope would lose about 1.5-1.8% of its original tensile strength per year. He also shared anecdotally that the military discarded life support nylon products after 10 years, or earlier, if abuse is evident. The article concludes with the statement that “Nylon gets weaker with age. Old rope is weaker than new rope and care of a rope has a far greater impact on rope life than age.” These statements might have been where the concept of retiring your rope after a maximum of 10 years, later incorporated into ASTM and NFPA standards, originated.

A by-product of teaching lots of classes is the we generate a lot of used rope, webbing and other software. That presents the same question that Bruce Smith had when doing his testing-is it used, abused or just old? We thought that by sheer numbers we might be able to determine if the 10-year recommendation for retiring equipment was valid. Instead of putting it into the trash we started saving the old stuff for eventual testing.

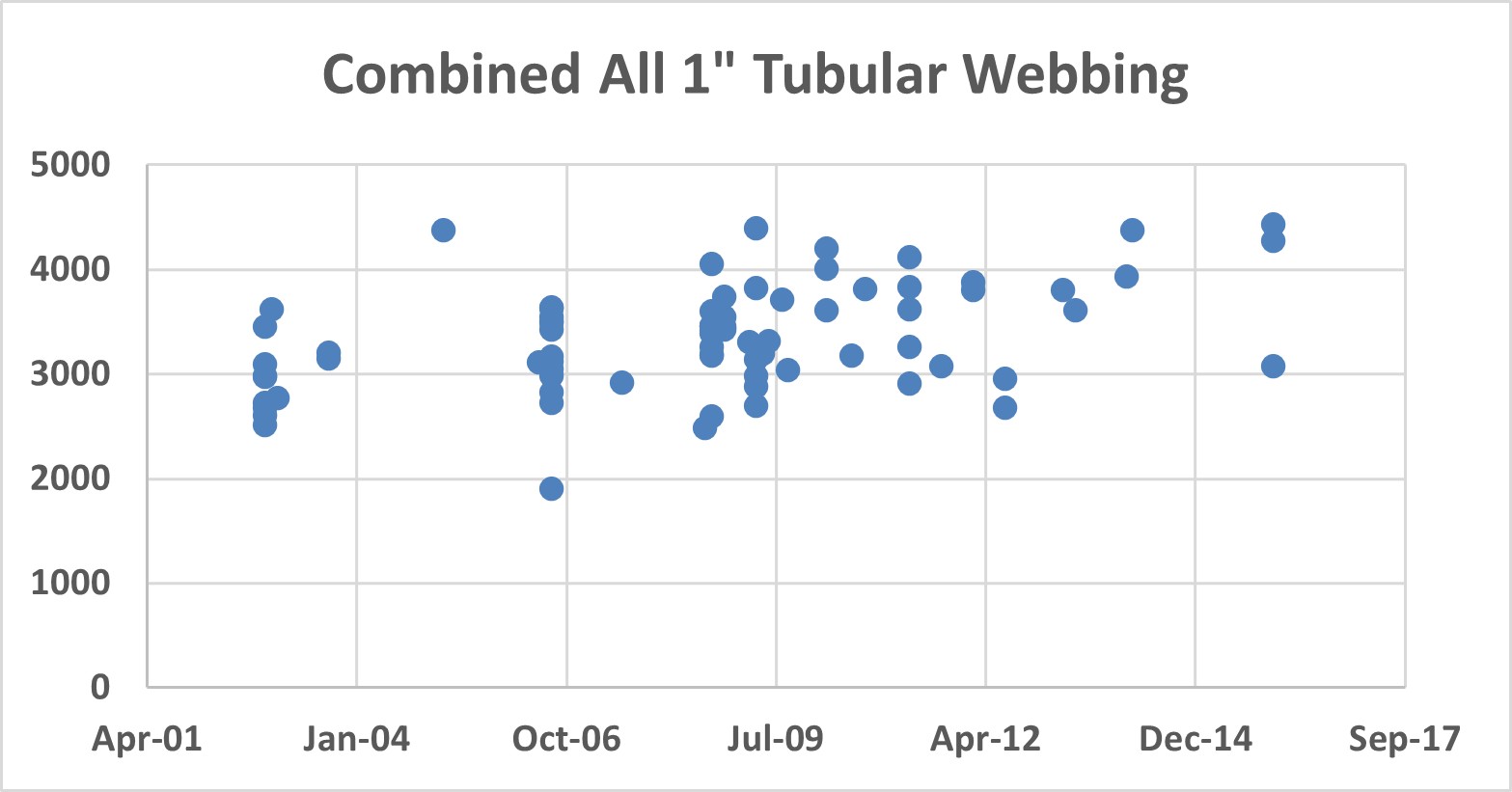

In 2018 we started the process and recorded the in-service date, color, type of loom (needle or shuttle) and where the sample broke for 95 pieces. This report does not include the samples without a date so we ended up with 77 pieces of tubular webbing, 12 sewn tubular webbing loops, 6 flat webbing, as well as smaller quantities of other equipment made with webbing such as anchor straps. Unfortunately, we could not come up with a correlation between age and breaking strength for any of it.

Some key points from this round of testing:

- The average age of all of the tubular webbing was 10.75 years old and the average break was at 3350 lbf which is 16% less than the catalog MBS of 4000 lbf.

- The average age of the sewn loops was 12 years and the average break was 92% of catalog. We tested 19 samples and only two broke at the stitching. The remainer broke at the shackle. We only had in service dates for 12 of those samples to calculate the average age and breaking force.

- One sample of the yellow needle loom was marked 3/05 but looked brand new and broke at 4378 lbf which is +9.45% of the catalog MBS.

- Only 9 samples of the tubular webbing broke between the drums (bollards) of the test machine. The rest of the samples broke at the tangent point of one of the 4” drums. If there was a middle mark on the test sample it was centered between the drums. In only one case did the webbing break at the mark which we think validates our previous testing and recommendation that using a Sharpie Laundry Marker is safe to mark the center of rope or webbing.

- The 4 anchor straps had an average age of 12.75 years, all were rigged in a basket configuration and all broke at the stitching on the smaller D ring but at an average of 12,447 lbf or 17% less than the catalog.

- We tested both the pocket and end to end on a 20-year-old multi loop strap and both broke above the catalog MBS of 1100 lbf for the pocket and 3800 lbf end to end.

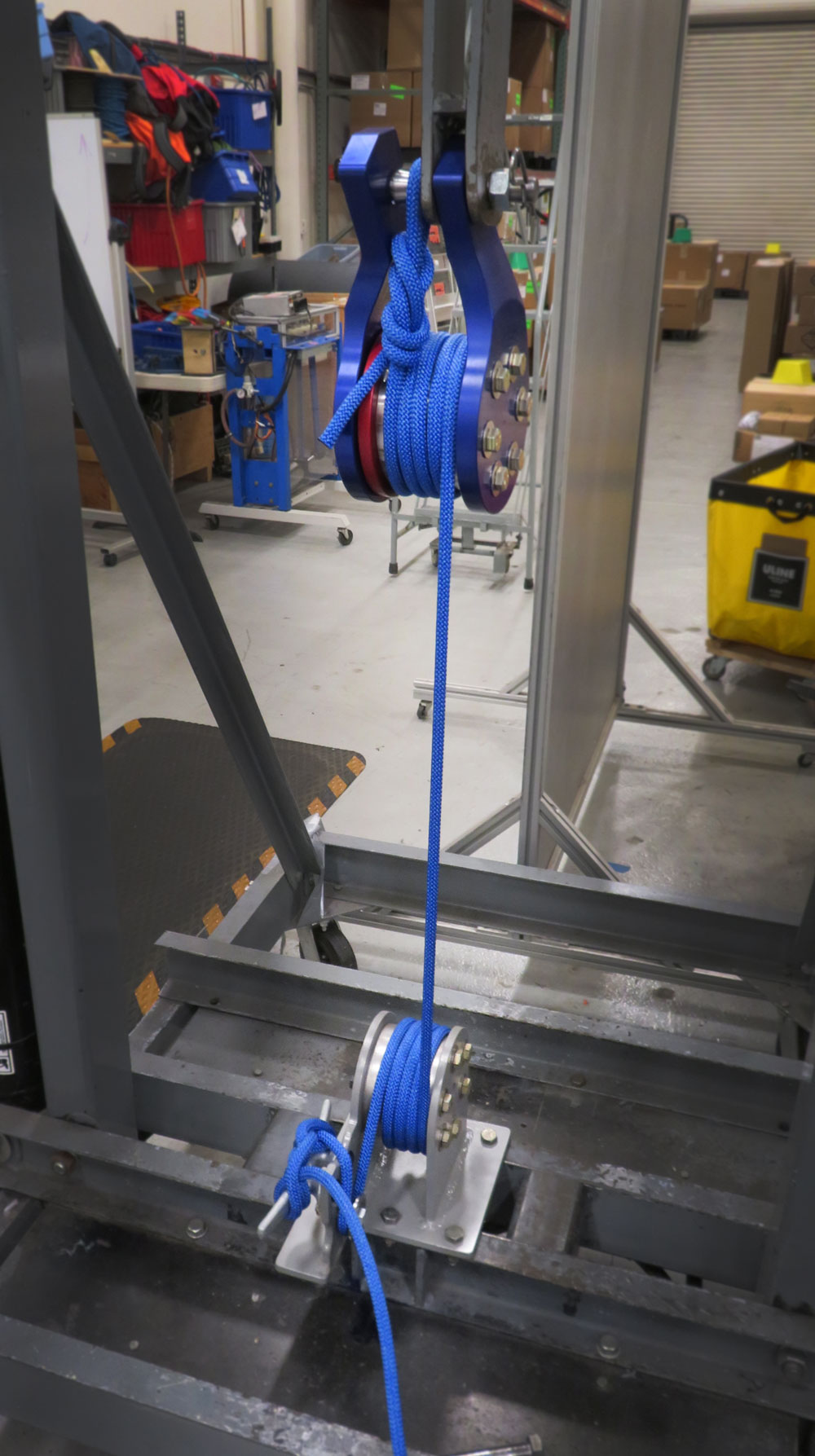

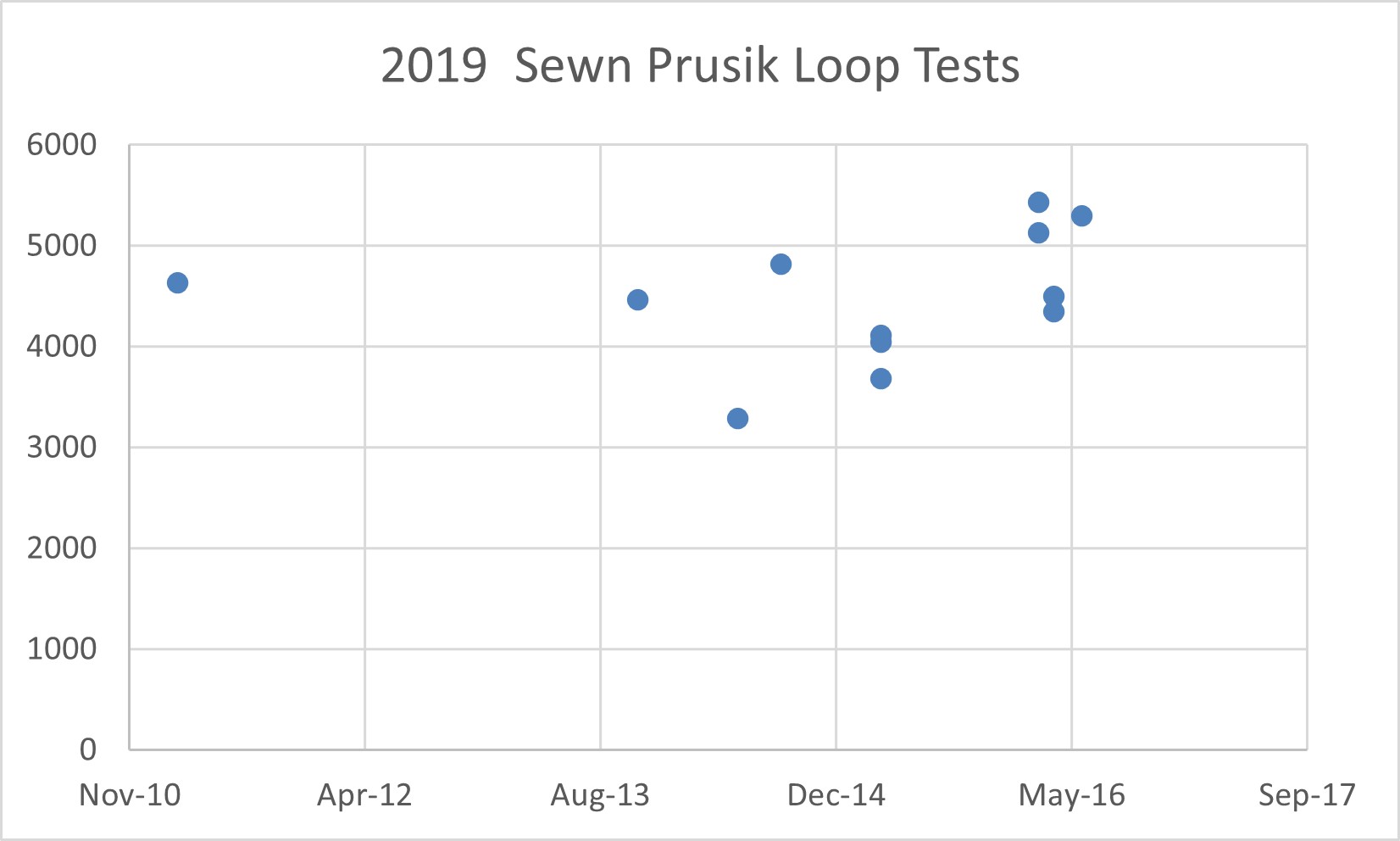

- We continued the testing in 2019 on 8mm sewn Prusik loops. We tested 27 samples but are only reporting those that had legible date of manufacture labels in place. Their average age was 3.9 years and the average break was 4480 lbf which is just slightly less than the advertised 4500 lbf.

- One of the samples broke at the stitching the rest broke at one of the carabiners that connect the sample to the test machine. It should be pointed out that all of the samples were taken out of service due to excessive wear which explains their low average age and probably the lower breaking force needed. Remember a prusik is designed to slip on the host rope and act as a force limiter. The average break on all 27 samples was just a little greater at 4489 lbf.

After a several year hiatus for the knot testing project, we started back on the investigation of the effects of age on software in January 2025. Our samples were all stored under normal conditions meaning in the dark except when being used, temperatures not exceeding 90°F etc.

- 50-year-old, never used, Goldline. As stated by Bruce Smith and others, twisted lay ropes are difficult to test due to their elongation. In some cases, we would exceed the 72” throw of the test machine and need to reset to break the sample. The average of our 5 samples was 4436 lbf. We did not have any control tests from 1974 and have seen published strengths for 7/16” Goldline range from 4400 lbf to 6400 lbf. While kernmantle construction has replaced this rope for climbing and rescue you have to admit that it performed well considering its age.

- Assorted used 1” tubular webbing-8 samples, Age ranged from 4-29 years old with 14.3 being average. Break average was 3622 lbf which is 90% of catalog MBS

- 2 pieces of 3/8” Goldline, 50 years old and short spliced to form a Prusik loop. Both broke in the middle of the span, not at the splice or carabiner. Average 3843 lbf.

- 2 Azzard straps mfd. 6/6/2011. Wrapped around drum and clipped to the triangular screw link in a basket configuration. Both broke the webbing at the screw link 8479 lbf & 8723 lbf well above the OSHA 5K for anchors.

- Multi Loop straps: 1/00 1258 lbf, 4/97 1146 lbf, 4/97 1229 lbf Catalog MBS is 1100 lbf

- Pick off strap buckle slipped at 4604 lbf then cut through. Catalog says it slips at 3372 lbf. No need to tie those off.

- Adjustable stretcher straps (14-24 years old) slipped at 3940, 4397, 3620 and one broke at 4840.

- 6 Black Mamba straps taken out of service per manufacturers recommended service life of 3 years. Average break at 14,280 lbf well above the catalog mbs of 11.016 lbf.

- Some additional tests that we conducted to complete our earlier testing on knots and contaminants.

- Tested 5 samples of new version G-11 with a Sharpie Magnum center line mark. The samples aged 3 ½ months before breaking at an average of 10,268 lbf. Well above the catalog 9,107 lbf or NFPA 9000 lbf. None broke at the mark.

- 11mm Static Pro tested 5 samples of used material that went into service in June of 2012 (12 ½ yrs old.) Average break was 7072 lbf for a strength loss of 10%

- A Figure 8 loop tied with that same material (12 years old 11mm) broke at an average of 4357 lbf for a 38% loss or 62% knot efficiency.

- A Bowline tied with that same 12-year-old material averaged 4353 lbf over 5 samples for a 38% loss due to the knot.

- A Poachers Knot also tied with that 12 old material averaged 4369 lbf or a 38% loss over 5 samples.

- The last three tests were to fill in some missing tests from our earlier work and to compare knot efficiencies between new and used rope.

- While this is all interesting information the issue is that all of the samples were used so the tests are not repeatable and the question is still-what happens purely because of age?

Current NFPA 2500 and ASTM F-1740 standards say to retire the rope after 10 years from date of manufacture. Neither mentions webbing but it has always been assumed that it applies to webbing products as well. Currently there is a proposal to include all “software” in the NFPA standard and to change the recommended retirement to 10 years from date of first use or 12 years from the date of manufacture. That is only a proposal and might change between the time this is written and the time you read it at ITRS. As we were conducting testing for this paper, we were asked by some members of the NFPA 2500 Committee if we had any additional information about aging on software to help justify or challenge the proposed changes.

Fortunately, we were able to find several types and sizes of unused ropes that were manufactured as early as 2001- well past the current 10 and proposed 12 years maximum. Some of our test samples were on the original spools and others had been cut into shorter-100- or 200-foot lengths, but were not put into service. Storage conditions varied but in no case was the material subjected to direct sunlight, chemicals or extreme heat.

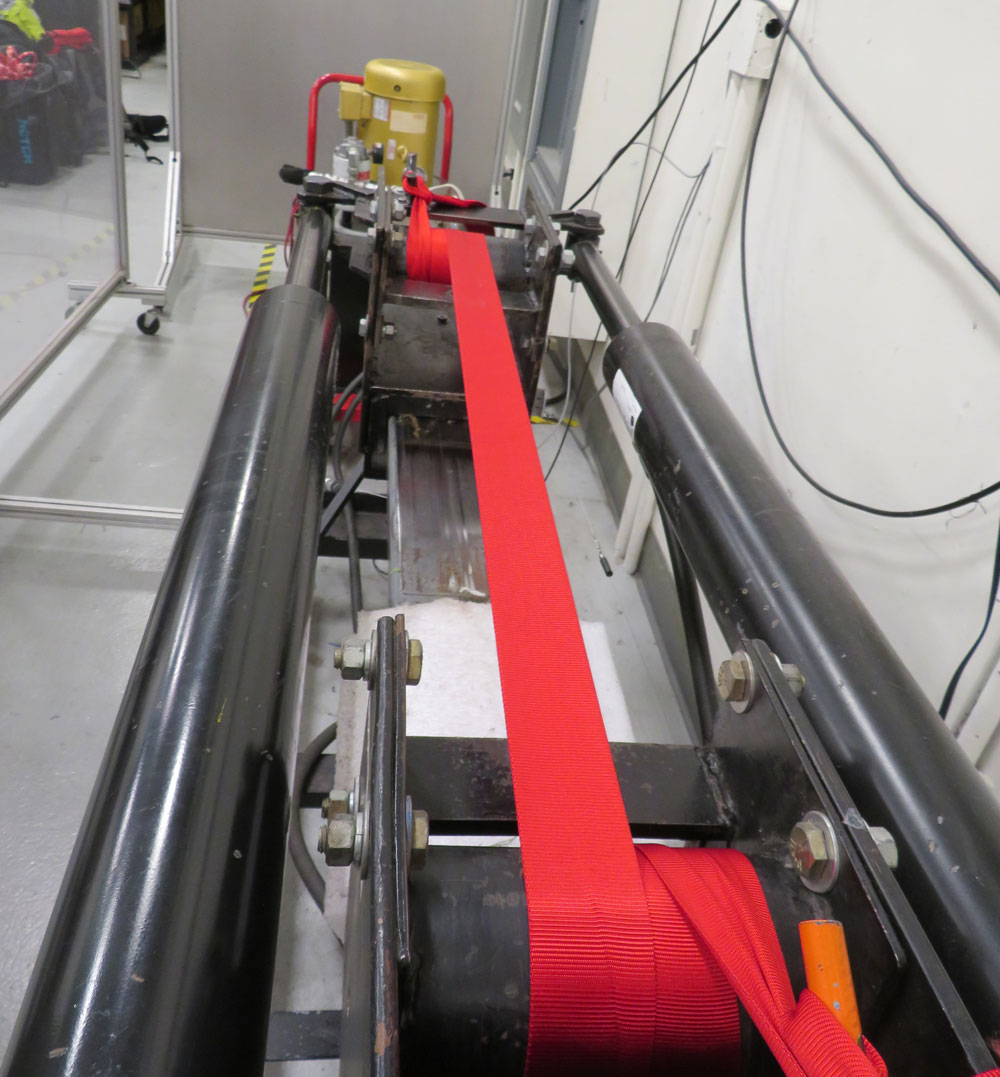

In NFPA 2500 (2022) the drum size for testing the breaking strength of rope increased from 4” to 5” in diameter. The Cordage Institute 1800 (2017) standard is still 4”. We had always used 4” so for consistency we continued using that diameter until this point where, whenever possible we tested samples on both sizes. NFPA does not have a test procedure for webbing so we followed the Cordage Institute. In future tests we will also use ASTM D6775 (2024) Standard Test Method for Breaking Strength and Elongation of Textile Webbing, Tape and Braided Material for a comparison. It uses a smaller diameter test drum.

We tested the rope samples using both 4” and 5” diameter test drums. When the test materials were made 4” was the standard but the current edition of NFPA 2500 requires 5”.

We do not have control sample information, meaning the actual rope strength from when it was manufactured. We used the catalog MBS to calculate average strength loss. Except where noted 5 samples of each were tested. Test conditions were 72-74° F with relative humidity at 50% (slightly less than CI-1800)

| Sample # | Description | 5” Diameter Drum | 4” Diameter Drum |

| 1 | ½” Yellow Nylon/Nylon-2011 | 10,342* | 9,702* |

| 2 | ½” -Red/White Nyon/Polyester 2001 | 9,486* | 9,254* |

| 3 | 7/16” Blue Nylon/Nylon-2001 | 6,633* | 6,402 (-1.6%) |

| 4 | 7/16” Red Nylon/Nylon-2001 | 4,818 (-25%) | 6,751* |

| 5 | 5 mm Poly over Technora-2001 | 4,608(-8%) | 4,243 (-15%) |

Average breaking force for samples exceeded catalog MBS

#1

½” Nylon/Nylon Yellow color, Manufactured 3rd quarter 2011 Catalog MBS 9500#

Average break force 10,342 lbf with the 5” drum all samples broke above the catalog MBS and

9,702 lbf with the 4” drum and 3 of the 5 samples broke above the catalog MBS

#2

½’ Poly/Nylon Red and White color, Manufactured 2001, Catalog 9250 lbf MBS

Average break force 9486 lbf with the 5” drum and all 5 sample broke above the catalog MBS

9254 lbf with the 4” drum and 4 of the 5 samples broke above the catalog MBS

#3

7/16” Nylon/Nylon Blue Color Manufactured 2nd quarter 2001 Catalog MBS 6500#

Average break force 6633 lbf with the 5” drum with 4 of the 5 samples breaking above the catalog MBS and 6402 lbf (-1.6%) with the 4” drum. 2 of the 5 samples broke below the catalog MBS

#4

7/16” Nylon/Nylon Red color Manufactured 4/2001 Catalog MBS 6500#

Average breaking force of 4 samples on the 5” drum was 4818 lbf (-25% from catalog) all samples broke below catalog and 6751 lbf using the 4” drum. 4 of the 5 samples broke above the catalog MBS.

#5

5mm Unidirectional Technora with Polyester sheath Manufactured 2001 catalog MBS of 5000#

Average of 5 samples using the 5” drum was 4608 (-8%) all broke at less than the catalog MBS and

4243 (-15%) on the 4” drum. In that case all 4 samples broke below the catalog MBS

Old but unused webbing was more difficult to obtain. We did find some, on the original spool that was manufactured in December of 2003 making it 24+ years old. It was needle loom, olive drab color and never used. There was only enough for 5 samples so we tested it on the 4” drums. The average breaking strength was 4656 lbf with the range between 4397 lbf and 4820 lbf, well above the catalog MBS of 4000 lbf for 1” tubular webbing.

The single sample dated 3/05 mentioned earlier that looked brand new and broke at 4378# (+9.45% of the catalog MBS) showed similar results.

We also found some old, but never used, still on the spool 2” tubular webbing. It was manufactured in March of 2013 (12+ years old) and had a catalog MBS of 7000 lbf. (Some catalogs say 8000 lbf.) The average breaking strength was 7117 lbf with a range from 6789 to 7674 lbf.

Not new off the spool and slightly dirty but without any wear issues were two lengths of 1” tubular put into service in 2015. Each was cut into 4 pieces for testing with average breaking strengths of 4090 lbf and 4087 lbf.

While not addressing rescue software one of our instructors compared the webbing used in motor vehicle seat belts to that used for harnesses. “Why do we cycle out a harness that is stored in better conditions than a seat belt which is often exposed to the sun and is definitely exposed to warmer temperatures for much of its life? There doesn’t seem to be a pattern of seat belts breaking and there isn’t a requirement to replace them after 10 years.”

Other thoughts on rope aging and breaking strength:

In 1967 Walt Wheelock stated “Recently it has been shown that usage is a greater hazard than aging.”

Bruce Smith in his 1988 article said “Care of a rope has a far greater impact on a ropes life than age.”

The UIAA In a 2000 article About Ageing of Climbing Ropes doesn’t give an exact number but states “Ageing caused only by storage can be neglected compared with aging during use.”

A study published in IOSR-JMCE To Study of Life Time Prediction of Nylon Rope using Ageing Property, Thermal Behavior and Physical Properties in 2014 essentially baked the rope at 70°C for up to 23 weeks to simulate natural aging of the rope. The average breaking strength loss of the test samples was only 1.4% after that period of time.

There was another study Ageing of climbing ropes with and without hydrophobic coating, published in 2024, where coated and uncoated climbing ropes were exposed to the weather, at altitude, in Austria for up to 4 months then cut into pieces and subjected to the UIAA drop test. The conclusion was that it had no impact on the safety of climbers but the number of falls the rope would take prior to failure would decrease. That study also included a lot of details about actual test set up-solar exposure etc. but best of all, for those readers who would really like to do more research, references to 49 other sources.

None of these exactly match our conditions for public safety rescue and we are not faulting their work. Most were based on 100% nylon climbing ropes while many of us are using Polyester or Nylon/Polyester blend ropes. The UIAA rating for climbing ropes is based upon the number of falls not the Cordage Institute or NFPA test methods for minimum breaking strength. Those standards did not exist when Bruce Smith did his study and his data came from a mechanical dynamometer not an electronic load cell. Wheelock did not provide test parameters for his data. It is probably unrealistic for several reasons but the best way to test the effect of age on rope is to buy a large quantity of rope from several different manufacturers store them together and at a regular interval cut 5 samples from each spool and test it. The same process would need to happen for 1” tubular webbing, 2” flat webbing of various types used for harnesses and anchor straps, etc. If anyone has done that, and has sample material available, please let us know.

Our limited testing reinforces the earlier statements by others that usage is a far greater factor for retiring rescue equipment than age alone. Yes, mark your rope and webbing and complete the labels on other software when you put the equipment into service. Store your software properly. Inspect it before and after each use and when it is taken out of service make sure it stays out of service.

Acknowledgements:

The authors wish to thank Kelly Byrne, John Camphouse and LeRoy Harbach for finding the old but unused rope and webbing we used for testing.

Thanks also to the management of CMC for providing sample materials and for the use of the test machines. The assistance and encouragement of the CMC Engineering staff led by Tyler Mayer. Specifically, Conner Warren for confirming our conclusions from the test results and helping with the graphs.

Finally thanks to CMC and PMI for their continuing contributions to the advancement of technical rescue through the co hosting of ITRS.

References:

Ropes, Knots and Slings for Climbers, Walt Wheelock, La Siesta Press 1967

Aging Rope, Nylon Highway #25, Bruce Smith, NSS Vertical Section January, 1988

About Ageing of Climbing Ropes, Pit Schubert, UIAA March, 2000

To Study of Life Time Prediction of Nylon Rope using Aging Property, Thermal Behavior and Physical Properties, Ms Pragati Gajbhiye & Mr Praveen Kumar Singh, IOSR Journal of Mechanical and Civil Engineering, Jul-Aug, 2014

Ageing of climbing ropes with and without hydrophobic coating, Daniel Sedláček, Martina Roso, Leano Viel, Nicola Perotto, Barnaby Caven, Michael Hasler and Werner Nachbauer Institution of Mechanical Engineers, Journal of Sports Engineering and Technology, Volume 238, 2024