CMC T95™ Multi-Attachment Guidance

CMC T95 sewn terminations are designed to accommodate multiple attachments. This may allow expert users (those comfortable with understanding and applying rigging loads and vectors, factors of safety, etc.) to configure the sewn terminations for a variety of applications including use as a focal point for a lightweight litter bridle. Connectors used for this purpose should be properly sized and positioned to prevent binding or torsional loading. Please see the figures below for a visualization of these angles and applications.

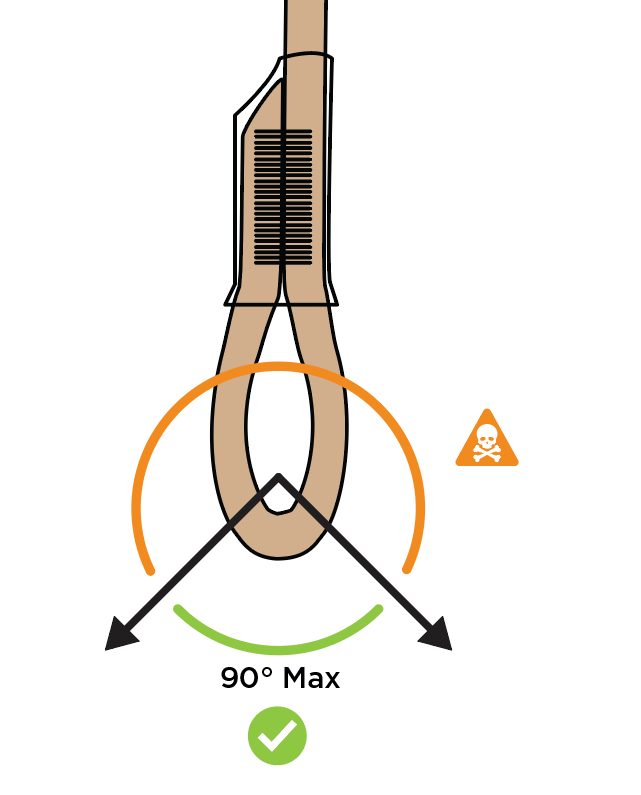

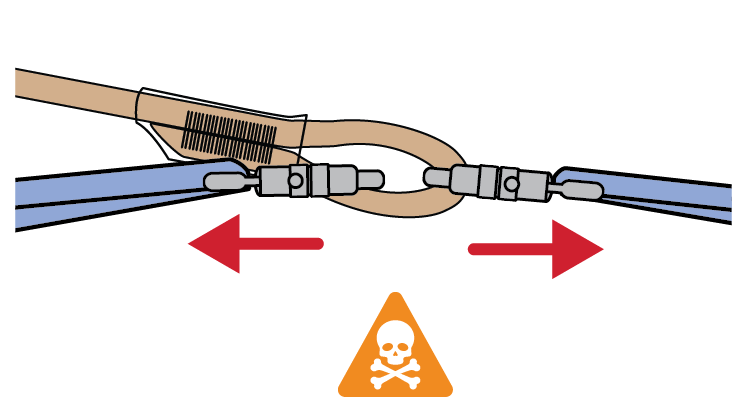

When loading CMC T95 sewn terminations with multiple attachments, it is critical to only apply load axially and never back against the stitching (Figures 1 & 2). Make sure to keep the internal angle of the rigging to a maximum of 90-degrees. Our testing shows minimal strength loss within this range. If the sewn termination is loaded at internal angles greater than 90-degrees, the stitching fails much lower than the marked MBS. Please note that sewn terminations should never be used as a link between multiple connectors (Figure 3).

Figure 1: Acceptable internal angle for multi-attachment loading.

Figure 2: Acceptable rigging application and angle for multi-attachment loading.

Figure 3: Never use sewn terminations as a link between multiple connectors.

Figure 4: example rigging for a lightweight litter bridle using CMC T95 and purcells.