ITRS 2023 Presentation: Down the Rabbit Holes of Small Diameter Rope Systems

The 2023 ITRS conference took place in St. Louis, MO. CMC Instructor Craig McClure collaborated with Jonathan Wilson, Justin Wheaton, Caroline Bull, Zachary Kline, and Clifford Freer to deliver the presentation titled “Down the Rabbit Holes of Small Diameter Rope Systems.” This served as a follow-up to last year’s award-winning presentation on 8mm rescue systems. Recognizing the increasing adoption of smaller diameter ropes and equipment in life safety situations, the team observed a lack of comprehensive testing for various systems within the rescue industry. To address this gap, they conducted a series of tests to determine the limits of these smaller diameter systems. Their research in the current year resulted in them receiving the “Best Overall” award for the combined paper and presentation. A link to their presentation is provided below and is also available on the ITRS website (itrsonline.org), alongside papers from other conference presenters.

About ITRS

CMC takes pride in co-founding and co-sponsoring the International Technical Rescue Symposium (ITRS), an annual gathering that brings together a diverse array of professionals in the technical rescue field. This includes experts in fire, mountain, cave, urban, industrial, and swift water rescue. At the symposium, presenters willingly share their research findings, testing outcomes, and field experiences for the collective benefit, encouraging attendees to reflect on and implement these insights. The symposium’s scale provides an ideal setting for extensive discussions and the exchange of knowledge.

DOWN THE RABBIT HOLES OF SMALL DIAMETER ROPE SYSTEMS

Jonathan Wilson, Craig McClure, Justin Wheaton, Caroline Bull, Zachary Kline, Clifford Freer

International Technical Rescue Symposium 2023

Abstract

Many individuals and teams have started to adopt smaller diameter ropes and equipment in life safety situations. Though various systems have come into use in the rescue industry, there has been a lack of testing. To fill this void we embarked on a series of tests to understand the limits of these smaller diameter systems.

Background

For years, various rope disciplines, including glacier travel, tactical and canyoneering, have pressured manufacturers to produce smaller diameter rope and compatible devices. Rope as small as 6mm has been introduced by Petzl (RAD system). The CTOMS TRACE System and Eldrid Glacier floss have been around for many years. Ropes in the 8mm range, made with a variety of fibers, have been aimed at canyoneering. Many devices have been released that accommodate these smaller rope systems, either on or off label, including the Black Diamond ATC Guide Alpine and the Mad Rock Safeguard device. Small diameter ropes and devices were first deployed by rope rescue technicians in situations where they had to travel long distances by foot to perform technical rescues and where weight is a factor in effecting a timely rescue. With a few exceptions, there wasn’t much drop testing data available for practitioners to make informed decisions about whether these small diameter systems were appropriate for them. Prattley(2021) and Spain(2019) presented some small diameter rope system testing. Prattley’s testing focused on individual components, many of which we wished to incorporate into our testing; however, 10mm ropes were used to test these components. Spain focused on rope systems at 9mm & 9.5mm. In consideration of this information, we set out to fill this void in the collective knowledge. We found ourselves like Lewis Carroll’s Alice falling down the rabbit hole; the more we looked the deeper it became.

Scope of Testing

The intended scope of testing was to find a reliable small diameter rope rescue system that will pass testing while simulating a single-person and/or two-person load edge fall. Ideally this system would also maintain control on a single device after failure of one-half of a two tension system. However, without an accepted test method for Twin Tension Rope Systems (TTRS) failure or tensioned line onto tensioned line, we used accepted belay competency methods with the assumption that passing such testing would indicate success in a TTRS system.

Standards of Testing

When considering how to conduct testing, we had to decide on a standard. This proved to be the first of many rabbit holes. We chose the ASTM belay tests at 100 kg and 200 kg with the measurement and success criteria adopted by NFPA and BCCTR. The British Columbia Council of Technical Rescue (BCCTR) Belay Competency Drop Test Method (BCDTM) was not available as a stand-alone document and no original source could be cited. We extrapolated the standards and method of the test from citations and references in other research papers and textbooks (Crandall, 2012, pg 81).

The British Columbia Belay Competency Drop Test Method (BCDTM) imagined a patient in a litter with a litter attendant and a combined mass of 200Kg falling 1m off an edge (tested without edge) with 3m of rope in service. The well-known standard test has served as the expected “gold standard” for comparative system performance in technical rescue.

A close examination of the BCDTM in regards to TTRS was done by Kirk Mauther; he concluded “it is clear that this test method is intended purely for DMDB (Dedicated Main Dedicated Belay) systems” (Mauthner, 2017). So we must further consider the test’s application to TTRS. If half a TTRS system can pass this test, essentially passing as a “belay”, we can reasonably conclude that we have a significant margin of safety in the worst case scenario of completely losing the other half of the TTRS. On the other hand, the entire reason the industry has shifted so drastically to TTRS, is that it should eliminate the potential for such an event to occur. So we further reviewed applicable test methods and standards for applicability.

The ASTM International (ASTM) Standard Test Method for Measuring the Performance of Synthetic Rope Rescue Belay Systems Using a Drop Test, F2436-14, mostly mirrors the BCDTM, but does not outline success criteria. Section 7.2.1 of this standard gives three different masses for the rigid test block, and asks the user to “select the most appropriate mass to the intended application”. The three test masses are Type II (100kg), Type IV (200kg) and Type V (280kg).

The National Fire Protection Association(NFPA) Standard on Life Safety Rope and Equipment for Emergency Services (1983 – 2017), has criteria similar to both the BCDTM and the ASTM standard, but further divides usage of the equipment into Technical (T), and General (G) rating. It should be noted that the scope of this standard states in section 1.1.5: “this standard shall not specify requirements for any rope or associated equipment designed for mountain rescue, cave rescue, lead climbing operations, or where expected hazards and situations dictate other performance requirements”. However, the language surrounding the differentiation between T and G rating was a useful tool in helping determine our test criteria. A comparison of these standards can be found in Table 01.

Testing the Tests

We consider rope rescue systems using less than 11mm rope to be T rather than G. With limitations in rope strength, we chose to start testing at the loads called for in the T standard and then increase loads to the point of failure. The working assumption is that more experienced practitioners operating in environments where T rated equipment is used can work within the load parameters specified.

Comparing the ASTM (type II) test of 100kg at 1m drop and NFPA T of 136 kg at 60cm drop, we wanted to quantify the resulting MAF. For this “test of tests,” we performed a series of tests in a knot-to-knot configuration without a descent control device. The testing yielded similar MAF between the greater mass/lesser drop and lesser mass/greater drop setups. (See table 2021.03 below for results.) We chose to use the ASTM (type II) because it was more easily compared to BCCTR BCDTM and NFPA tests, and would allow for easier increases of mass that aligned with a known test method.

Table 1: Comparison of Test Standards

| Test Standard | Mass | Drop Distance | Rope in Service | Allowable System Extension | Allowable Max Arresting Force (kN) |

| BCCTR Belay Competency Test Method | 200kg | 1m | 3m | 1m | <15kN |

| ASTM F2436-14 (2019) (Type II) | 100-200Kg | 1m | 3m | 1m | – |

| NFPA T1983-2017 8.6.4.5 | 136kg | 60cm | 3m | 1m | <15kN |

| NFPA – G | 280kg | 1m | 3m | 1m | <15kN |

Maximum Arrest Force

In Table 1 above, all test standards consider a MAF of less than 15kN a success. However, knowing that substantial research has concluded that these forces would have a detrimental, if not fatal, result on a human body, we wanted to determine a MAF that we felt would be more acceptable given this consideration.

The Emergency Management British Columbia (EMBC) Rope Rescue New Initiatives Fund (NIF) Equipment Testing Summary Report dictates that, due to human tolerances and “current fall arrest standards/regulations,” sudden arresting forces should be limited to a 6-12kN range. The EMBC report uses 6kN as a maximum force a single rescuer could endure, and then assumes that with two rescuers, the forces imparted could reach 12kN because each human on the end of the system would absorb roughly 6kN. In Code of Federal Regulations Part 1910 Subpart I, Section 1910.140(d) the Occupational Safety and Health Administration (OSHA) has criteria for the design and implementation of personal fall arrest systems. These state that you must “limit the maximum arresting force on an employee to 8kN” (NIOSH CFR 29)

Scientists in the 1940s wanted a way to identify the level of damage the human body would experience during the deceleration forces exerted by ejection seats in airplanes. These studies concluded that 16kN would result in serious injury or death. In 1979, OSHA decided on 8kN as an acceptable limit by dividing the results of the European studies in half (Rigid Lifelines, 2013). Section 1910.140(d) is the most clearly outlined regulation or guideline for this testing metric for falls with humans available. OSHA also has similarly developed criteria for body belts, in which the MAF cannot exceed 4kN. That being said, neither criteria assumes the harness arresting the fall is a climbing style or rescue style harness with a pelvic or sternal attachment. Seeing that most harnesses that rescuers use fall somewhere between these two criteria, we choose to reduce the MAF of 8kN to 7kN, to address the dissimilarities in harness styles.

Releasability

All of the cited test methods state that the belay system should be functional after the arrest event. “Functional” is not defined and has many interpretations. For the handled devices such as the Clutch, 540, MPD, ID, etc, functional is interpreted as the handle retaining function and the ability of the load to be lowered. For a tandem prusik belay, the use of a release mechanism is required. Therefore, it must be considered as a system of prusiks and release mechanism. Knowing we were testing handled devices, friction plates, and friction hitches, we adopted the measure of the component being releasable post arrest event as a binary measurable data point. While we evaluated each component on individual performance, we recognized that components would be combined as a system. Our aim was for a system that remained releasable without addition of extra components to preserve the intent of lightweight systems.

Components vs Systems

Component performance versus system performance remained an unanswered question. If devices and hitches are combined into an operating system do the individual components need to perform to belay competency standards? Or does only the entire system, as used, need to perform to standard? Out of curiosity and lack of consensus among the testing team we decided to first test individual components and then as a system. At the time, we felt that if each component met standard individually there was an added margin of safety, such that two is better than one. This will be discussed more in the conclusion.

The ‘Mechanical Hand’

NFPA and ASTM also call for a mechanical hand with consistent 50N back pressure. While ASTM specifies a design, this proved to be another rabbit hole as we noted the design would provide variable pressure during a drop and elected to use a consistent human operator applying reasonable operating tension on the brake side of the system. Subjective notes on changes in pressure are included in test results.

2021 Testing

In 2021, several things came together to make our testing possible. We were granted access to the Air Force 351st Special Warfare Training Squadron’s tower facility at Kirkland Air Force Base. This 5-story steel tower was perfect for drop testing. The facility had adequate height, space to work, and solid anchors to set up our testing. Hundreds of meters of Blue Water 8mm Canyon Extreme rope, dozens of 7mm and 8mm Bluewater VT Cords, Sterling 8mm Canyon Lux Rope, and PMI’s 8mm Explorer Pro Rope were donated to the project. The 2021 testing series totaled 97 drops.

Modern Small Diameter Rope

Looking purely at the cross-sectional area of rope we can see that the area and, hence, mass reduction by decreasing the diameter is significant . Eight millimeter (50.26mm2) rope is 71% of the cross sectional area of 9.5mm (70.88mm2) rope, and 52% of cross sectional area of 11mm (95.02mm2). Small diameter rope currently comes in a variety of sheath and core materials (See Table 2)

Table 2: 8mm Ropes used in testing

| Manufacturer | Rope | MBS (kN) | Sheath | Core |

| Bluewater (BW) | Canyon Extreme | 24.5 | Technora | HMPE |

| Sterling (Lux) | CanyonLux | 24.3 | Technora/Polyester | Spectra/Polypro |

| PMI | Dura-Shield Explorer | 27.8 | Technora/Polyester | Dyneema/Polypro |

Devices

The devices used in 2021 included Black Diamond’s ATC Guide Alpine, Mad Rock Safeguard, Conterra Scarab Ti, and Petzl GriGri 2. Many thanks to the representatives of all the manufacturers that supported our testing, we could not have afforded to purchase this equipment on our own.

Anchoring

In an effort to reduce the amount of force absorbed by the anchor and anchor interface, the testing area was set up using a very large girder as a top anchor, using Twin-Path synthetic round slings, with less than 1% elongation at their rated capacity of 20,000lbs. A Rock Exoctica Enforcer load cell was rigged to the anchor. The load cell was calibrated to zero in place and set to 500 samples/sec to capture in kN.

Test Mass 2021

The test mass was composed of 20kg (45lbs) plates slung together with an industrial rigging strap. A large shackle served as a focal point for: the test rope sample, Sea Catch TR5 release, and test mass retrieval rope.

Test Methods 2021

The rope sample was marked 3m from the bottom terminal. The rope sample was reeved through the device, and the test mass was lowered onto the test rope. Any ‘slip’ was measured and recorded. The test was reset if the slip was more than 5 cm. The test mass was then raised one meter, measured at the raising rope. The test mass was released using the Sea Catch. The max arrest force and amount of rope that slipped through the device were recorded. The device was then evaluated for continued function, and releasability. Any damage to the device and the rope was evaluated and recorded.

Variables

There are several variables that can be introduced to this type of testing, we made an effort to identify and reduce the effect of these variables. For example, the various prusik hitches were tied by the same person throughout the testing. If the system required an operator to hold the rope, the same person performed the task as ‘operator’ throughout the testing.

Knot Tightening

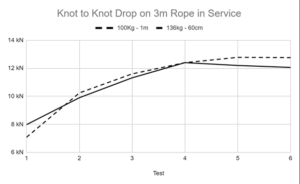

Yet another rabbit hole we fell down in the testing was the amount of energy absorbed by knot tightening. A series of tests were set up to compare MAF generated in the ASTM type II and NFPA T, and we observed a similar trend in the results. Repeated falls on a knot-terminated rope affected the amount of energy “felt” by the load. The MAF of successive drops increased. Each knot was an ABOK 1010

Bowline (Ashley, 1956)

Figure 3 Results of ASTM type II and NFPA T MAF Comparison

While the purpose of the tests was to compare MAF of ASTM and NFPA tests, an interesting trend appeared. We did determine there was little difference in MAF between the two standards. In both tests, the first drop was in the 7-8KN range, second at approximately 10kN, third 11.5kN, and then a plateau at approximately 12kN. After seeing this curve in test series 1, we posited that it was either a product of rope stretch or knot tightening. For the test series 2 we used the same rope and saw nearly the same curve (Figure 3) .

Valdotain Tresse vs Schwabisch vs Distel Hitches

The contemporary popularity of eye-to-eye open prusik cords in rescue has raised the question about which hitch a team should use in their rescue systems. There exists confusion over the term “VT” because Bluewater Ropes sells their aramid eye to eye hitch cord as the “VT Prusik Cord”. The VT Prusik Cord can be tied in a variety of hitches, including: the Valdotain Tresse, Schwabish, and Distel Hitches.

The Valdotain Tresse (VT) hitch was tied 3×3 (3 wraps x 3 crosses) for all of our tests. This hitch has a steeper learning curve for practitioners to tie and inspect, but it offers more ‘control’ with its ability to feather the resistance with one hand.

The Schwabish hitch, also known as ‘Max over 1’, has become a popular hitch used with a prusik minding pulley in mechanical advantage systems. It has an easier learning curve than the VT, but it can be tied incorrectly with the ‘max’ wraps tied away from the load.

The Distel hitch is a slight variation on the Schwabish, with the eyes coming out on either side of the main rope rather than the same side, as on the Schwabish. The Distel has been found to ‘ride’ some prusik minding pulleys better than the Schwabish. Extensive testing of these hitches have been presented in the past (Gibbs, 2019).

We tested several variations of hitch ties on 8mm rope at both 100kg and 200kg.

Table 4: Hitch Testing on 8mm Rope

| Hitch | Rope | Mass (kg) | N | System Extension (mm) Max / Min /Avg | Arrest Force (kN) Max / Min / Avg | |||||

| Valdotain Tresse | BW | 100 | 5 | 540 | 170 | 363 | 5.48 | 3.40 | 4.56 | a |

| Lux | 100 | 2 | x | x | x | x | x | x | b | |

| BW | 200 | 2 | GN | GN | GN | 3.90 | 2.28 | 3.09 | c | |

| Schwabisch (Max/1) | BW | 100 | 2 | 35 | 20 | 27.5 | 8.48 | 8.08 | 8.28 | d |

| Lux | 100 | 1 | – | – | 75 | – | – | 6.48 | e | |

| Distel | BW | 100 | 1 | – | – | 32.5 | – | – | 7.64 | |

GN = Load to Ground

- One test the VT slipped all the way to the ground. In several tests the rope experienced ‘glazing’ where the hitch would not hold again.

- Hitch would not hold 8mm Sterling CanyonLux, test could not be performed.

- All tests went to the ground, VT unable to catch 200kg drop.

- 1st test rope not releasable / 2nd test visible rope damage.

- Polyester carriers in CanyonLux rope glazed, sheath milked down around hitch.

The Valdotain Tresse hitch worked well on Bluewater Canyon Extreme 8mm rope for the 100 kg mass, but the hitch wouldn’t statically hold the Sterling CanyonLux rope to even perform the test. The Valdotain Tresse hitch couldn’t catch the fall of the 200 kg mass, all tests went to the ground. The Schwabish hitch was very effective at gripping the Bluewater Canyon Extreme 8mm rope, perhaps too effective. It arrested the fall in such a short distance that it produced max arrest forces beyond our 7kN limit, and beyond the OSHA 8kN limit. The Schwabish hitch melted the polyester carries of the Sterling Canyon Lux rope when arresting the fall, deforming the rope and reducing its diameter. The Distel hitch produced similar results to the Schwabish hitch.

Observed Changes In Rope and Cord Sheath

Some of the drop tests of Technora fiber hitches on Technora fiber ropes resulted in what we called ‘glazing’ for lack of a better term. The Bluewater Canyon Extreme rope sheath is mostly Technora with a single polyester carrier of polyester. Technora fibers do not melt, but rather start to decompose at temperatures above 500° C (Marlow Ropes, 2023). The ‘glazing’ witnessed at the contact point of the hitch and the rope seems to be the beginning of a decomposition process. The rope was stretched and became stiffer as a result of the pressure from the hitch tie, this stiffness could be ‘worked’ out and the rope appeared normal after a short time. These sheath changes negatively impacted friction hitch effectiveness. Industry experts (Delaney, Hunt, Koprek, 2023) agreed there is not a term for this phenomena, so we noted it as “Work Hardening”. We defined work hardening as a temporary change in rope sheath texture and stiffness that could be worked out back to nearly original condition. The Sterling CanyonLux and the PMI DuraShield Explorer both have a high percentage of polyester carriers in the sheath. We observed a high amount of actual glazing in these ropes, and the polyester strands were smeared and deformed. Unlike the technora sheath ropes, the poly/blend rope glazing was a permanent change in the composition of the sheath. They could not be “worked out” of the rope, and the sheath remained compressed and shiny. Additionally, the poly/blended ropes showed significant compression resulting in decreased rope diameter which decreased hitch performance on subsequent uses of the same section of rope.

Table 5: Device only on 8mm Bluewater Canyon Extreme Rope using 100kg & 200kg

| Device | Mass (kg) | N | System Extension (mm) Max / Min / Ave | Max Arrest Force (kN) Max / Min / Ave | Release Rate | |||||

| ATC Guide Alpine | 100 | 5 | 730 | 320 | 540 | 4.88 | 3.48 | 3.98 | 100% | a |

| 100 | 2 | 470 | 340 | 405 | 4.96 | 3.76 | 4.36 | 100% | b | |

| 200 | 5 | 930 | 680 | 838 | 6.06 | 5.20 | 5.71 | 80% | c | |

| MadrockSafeGuard | 100 | 2 | *100 | *70 | 85 | 7.32 | 7.02 | 7.17 | 50% | d |

| GriGri2 | 100 | 5 | 520 | 390 | 462 | 4.08 | 3.32 | 3.66 | 100% | |

| 200 | 2 | GN | 1350 | – | 5.68 | 4.16 | 4.92 | – | e | |

| Münter | 100 | 5 | 1890 | 930 | 1214 | 3.86 | 2.32 | 3.14 | 100% | |

| Super Münter | 100 | 2 | 420 | 350 | 385 | 5.72 | 4.22 | 4.97 | 100% | |

| Scarab Ti | 100 | 5 | 880 | 200 | 438 | 6.08 | 2.85 | 4.19 | 100% | f |

- Regular Friction Mode

- High Friction Mode

- 1 drop on high friction jammed rope, not releasable

- Sheath damage

- First drop, operator could not catch fall, load hit ground. Second drop difficult to catch w/o anticipation

- Experimentation found that reeving the Scarab with 2 horns would not hold the load in place

- and 4 horns wouldn’t allow for lowering. The only functional reeve was 3 horns.

Black Diamond ATC Guide Alpine

Overall the ATC Guide Alpine performed within the limits of the tests. We tested both ‘regular friction mode’ and ‘low friction mode’ on the 100kg test mass, and the ‘regular friction mode’ on the 200 kg test mass. During the 200kg test series the rope became ‘jammed’ in the device after arresting the load and could not be released. The other four drops in the series were releasable after arresting the drop. The BD ATC Guide Alpine doesn’t satisfy the ASTM standard as it required more than a 50N input on the brake strand of the rope. In fact, it requires a component operator to arrest the fall.

Madrock SafeGuard on 8mm Rope

The most dramatic results of this test series was the severe damage to the rope imparted by the Madrock SafeGuard. The sheath was completely cut and several core strains were either cut and/or melted.This has been coined the “Anvil Effect”; the cam acts as a hammer against the brake surface damaging the rope sheath. The device could be released on one test and not the other. These results gave the team pause as the Madrock SafeGuard is currently being used in the fashion by several teams. Considering these failures at 100kg, we held off on testing the Madrock SafeGuard at 200kg for the time being.

Petzl GriGri2 on 8mm Rope

Petzl lists the rope size range 8.5-11mm and specifically states , so this is operating well outside the manufacturer’s recommendations. The GriGri2 performed within limits for all tests at 100kg. At the 200 kg mass the operator couldn’t maintain control of the brake strand of the rope resulting in a ground fall. The second test the operator was able to arrest the fall, but only because they knew it was happening, and using a considerable effort on the brake strand of the rope. This resulted in over a meter of system extension.

Münter/Super Münter on 8mm Rope

The Münter in this series of tests was operated one handed with the brake strand held 15° off the running end of the rope. The operator reported having to anticipate the fall in order to arrest it. 3 out of 5 test resulted in system extensions beyond 1 meter.

The Super Münter performed with the limits of the 100kg test operated with one hand. All Münter tests were releasable after arresting the fall.

Scarab Ti

The Titanium Scarab presented an interesting variable in testing bar and/or horned style lowering devices. Once the appropriate friction mode was identified, the Titanium Scarab performed within the limits of the tests. Per the manufacturer, the first horn wrap is required, and each subsequent wrap is used to adjust friction. Two horns did allow for control of the load after the drops, whereas a fully-reeved Scarab, using all 4 horns, was too much friction to lower the load. The appropriate friction mode was 3 horns. This was addressed again in the systems testing with hitches introduced. With the exception of poly blend sheath ropes load control at 100kg was acceptable. We tried adjusting the friction on the Scarab. A drop with two horns engaged had 880mm of extension and the hitch would not hold the load after the operator released. On 4 drops with 3 horns engaged, the average extension was 327mm.

Table 6: Systems (Device and Hitch) on 8mm Rope using 100 kg Mass

| Device / Hitch | N | System Extension (mm) | Ave Max Arrest Force (kN) | Pass Rate | Release Rate |

| ATC Guide Alpine VT3x3 | 13 | 388 | 3.93 1 | 86% 2 | 77% 3 |

| Scarab VT3x3 | 5 | 438 | 4.18 | 100% | 100% |

| ATC Guide Alpine Operated with moving load VT3x3 | 7 | 764 | 1.95 | 87.5% | 87.5% |

- Average on PMI Durashield Explorer 5.6kN

- VT failed to hold on one test prior to drop on Canyonlux

- Hitch never releasable on PMI Durashield Explorer

Table Table 7: Systems (device and Hitch) on 8mm BlueWater Canyon Extreme using 200 Kg Mass

Device / Hitch | System Extension (mm) | Max Arrest Force (kN) | Release | Notes |

ATC Guide Alpine High Friction / VT3x3 | 510 | 6.34 | Y | All load on ATC, none on hitch |

ATC Guide Alpine Regular Friction / VT3x3 | 1060* | 4.92 | Y | *Arrested <1m, but once operator released tension load slipped to 1.06m |

Scarab 3 horns / VT3x3 | 1560 | 3.4 | Y | Hitch not grabbing, all on Scarab |

Scarab 4 horns / VT3x3 | 840 | 4.25 | Y | Hitch not grabbing, all on Scarab |

Operated System Tests

The ATC Guide Alpine system was set up horizontally as it would likely be operated. The rope was led through a pulley high directional. The load was lowered

slowly with the release point unknown to the operator, but as close to 3m rope in service as possible. System extension was measured from the release point to the final resting position of the load. We found it more successful if the brake strand behind the ATC was run through a 180deg carabiner redirect at the anchor. This included a test where the operator dropped the brake strand completely. Dropping the brake resulted in slightly higher MAF of 3.26kN and the only time the hitch was not releasable. This setup also provided favorable ergonomics for the operator.

This series highlights the need for complete systems testing in the manner of use. Performance of the hitch changes when paired with a device holding tension behind the hitch.

When in high friction mode, the ATC arrested the load within acceptable ranges, and the hitch did not grab. While it arrests the load in acceptable parameters it does not result in what would be considered a hands free stop. Regular friction mode shared the load between hitch and device with some slip if the operator released grip. In systems with skilled operators and more specifically in TTRS mirrored systems is a hands free stop required?

With a hitch in front of the scarab reeved at 3 horns it proved ineffective and resulted in significant system extension. With 4 horns the system extension was shorter but 4 horns would not allow for lowering of the load which is problematic for actual rescue operations. An operator set for proper lowering friction would not have enough friction to catch a falling load. Placing a hitch or device behind a Scarab is common practice and should be tested.

2021 Testing Discussion

The 2021 testing series raised as many questions as it answered. One interesting concept was how the tests on individual components resulted in near failing or failing our criteria, but put together in a system (device and hitch) performed well within comfortable operating limits. Must components alone catch the falling load within criteria?

2023 Testing

After the results of the 2021 testing were considered, we decided to revisit some of our results with better testing methods, as well as explore how the various devices and methods operated using 9.5mm rope.

Changes in Measurement Method

A significant change to the testing method was the introduction of laser measuring devices. In the 2021 series the test mass was raised 1m measuring the distance using the hauling rope. At ITRS 2022 a colleague pointed out that our method resulted in only measuring slip through the belay hitch or device and was not a true and complete measure of system extension. To correct this we used a laser measuring device against an established datum directly to an established point on the test mass. We were able to refine the consistency of the 1m drop for the test mass. The measurement of the overall drop of the mass was also refined. In 2021, the drop was measured from the device to a mark on the rope. In the 2023 series, the overall drop was measured using the laser measuring device, providing improved data.

Test Mass

The test mass was also improved for the 2023 series. A steel test rig was fabricated that allowed the mass plates to be stacked together. This rig provided an improved rigidity to the test mass as well as a consistent point from which to use the laser measuring devices.

In the 2021 test series, the terminal knot was observed to absorb some of the energy of the drop. For the 2023 test series this variable was addressed by having each drop conducted on a freshly tied knot tied by the same person throughout the series. The terminal knot used was an ABOK 1010 Bowline (Ashley, 1956) with a Yosemite finish. The 2023 series consisted of 86 drops, on 36 different rope samples over 3 days.

Revisiting MadRock Safeguard on 8mm Rope

One of the most dramatic results of the 2021 test series was on the MadRock Safeguard. In 2021 we made an N=2 drops on the Mad Rock Safeguard, both resulting in rope failure. The team decided to revisit these results with a test series of 5 to confirm our findings.

Table 8: Madrock SafeGuard on 8mm rope using 100 kg Mass

| Rope | System Extension (mm) | Max Arrest Force (kN) | Notes |

| BW Canyon Extreme | 160 | 7.14 | Complete desheath, all core strands intact. Not releasable |

| Sterling CanyonLux | 260 | 6.96 | Complete desheath, no damage to core. core flattened. Not releasable. |

| Sterling CanyonLux | 190 | 8.20 | Complete desheath, hard to open device, broken strands and work hardening observed. Not releasable. Shearing of blue material on cam of mad rock |

| Sterling CanyonLux | 230 | 8.18 | Complete desheath, hard to open device. Broken strands, work hardening observed. Not releasable. |

| Sterling CanyonLux | 160 | 7.30 | Complete desheath, hard to open device. broken strands, work hardened (more than others). Not releasable. |

No damage to Mad Rock Safeguard device observed during any tests

MadRock SafeGuard on 8mm Rope

The 2023 test series confirms the 2021 test series results of the MadRock Safeguard on 8mm rope. We would not recommend using the device and rope combination in a situation where a person could take a factor 0.3 or above fall on 8mm rope. Consider the consequences of an error negotiating an edge at the beginning of a rappel, or employing the Madrock Safeguard as a work restriction line or edge line in terrain of consequence. The Safeguard cam has a flat leading edge that can rotate when under load to come in contact (or very nearly) with the opposing braking surface. This design allows the device to completely close on the rope pinching it between two metal surfaces with little relief. By comparison the Grigri has a curved leading edge matching the profile of the rope and when the cam is rotated under load there is still a gap between the cam and braking surface. We named the metal on metal contact of cam and braking surface the “anvil effect”.

9.5mm Rope Rescue Components and Systems (2023)

We found the tolerances for variables in 8mm systems to be narrow in the 2021 testing series. The margin between success and disaster was unpredictable because of those variables, which include rope construction, hitch tie quality, operator skill, reaction, and attentiveness. There are bespoke 8mm systems such as the Highnovate QRAB, but because of cost and availability those were not considered for the 2021 testing. Looking to increase the ability to absorb the energy created by the drop tests we considered increasing the mass/diameter of the rope used in the system. While there are other rope sizes offered in the industry, the Sterling 9.5mm Canyon Tech and Tactical Response rope met the strength and sheath construction aspects we look for in rope rescue systems (Table 9). Additionally these 9.5mm ropes can meet NFPA -T classification where 9mm rope cannot. We felt this may be a benefit or requirement of practitioners considering lighter weight systems.

Table 9: Sterling Rope Specifications

| Manufacturer | Rope | MBS (kN) | Sheath | Core |

| Sterling | 9.5 mm Canyon Tech / Tactical Response | 30 | Technora | Nylon |

Sterling Canyon Tech and Tactical Response are nearly identical ropes with Canyon Tech having an additional colored strand in the sheath. Tactical response carries an NFPA T marker tape in the core.

Table 10: Device Testing on 9.5mm Sterling CanyonTech/Tactical Response Rope

| Device / Hitch | Mass (kg) | N | System Extension (mm) Max / Min /Avg | Arrest Force (kN) Max / Min / Avg | |||||

| MadRock Safeguard | 100 | 5 | 114 | 97 | 105 | 7.28 | 6.72 | 7.10 | |

| 200 | 5 | *787 | 282 | 479 | 9.26 | 7.86 | 8.57 | a | |

| Petzl GriGri | 100 | 5 | 229 | 185 | 210 | *6.80 | 6.12 | 6.51 | |

| 200 | 2 | 673 | 651 | 662 | 8.58 | 7.22 | 7.90 | b | |

| BD ATC Guide High Friction Mode | 100 | 5 | 556 | 477 | 507 | 4.02 | 3.36 | 3.62 | |

| 200 | 5 | 2525 | 1376 | 1998 | 3.30 | 2.72 | 2.76 | ||

| BD ATC Guide Low Friction Mode | 100 | 5 | 1116 | 978 | 1034 | 2.58 | 2.46 | 2.50 | |

| Münter | 100 | 5 | 1123 | 487 | 790 | 3.52 | 2.50 | 2.93 | |

| Super münter | 100 | 5 | 447 | 145 | 277 | 5.82 | 3.36 | 4.76 | |

| 200 | 5 | 769 | 329 | 582 | 8.06 | 4.92 | 6.55 | ||

Notes:

- 1 out of the 4 drops in this series broke the rope and went all the way to the ground.

- The GriGri showed damage to the main structural pin and could not be opened at 200Kg tests.

Somewhere between 100 kg and 200 kg is the point at which the Safeguard damages rope. This testing does not define that point. Nor does it define the point at which structural failure of the Grigri occurs.

Madrock Safeguard on 9.5mm Rope Discussion

The MadRock Safeguard performed better on 9.5mm rope than on 8mm rope. Throughout the 100kg test series, there was no damage to the rope or the device. Four out of the 5 tests resulted in max arrest forces above 7kN, the highest being 7.28kN. System extension was within acceptable distances ranging from 97-114mm. The device ‘fuzzed’ the rope where contact occurred during the drop, but the rope was deemed usable afterwards. The device was releasable after all five tests.

At the 200 kg mass test series the MadRock Safeguard didn’t perform as well. In 1 out of the 5 tests it broke the rope, sending the test mass to the ground. The rope left in the device was not releasable. In the other four tests, the MadRock Safeguard broke the sheath each time, leaving the core exposed with broken and/or melted core strands observed. The maximum arresting force ranged from 7.86-9kN with a system extension ranging from 286-787mm. The rope was only releasable in 3 out of 4 of these remaining tests.

Petzl GriGri on 9.5 Rope

The Petzl GriGri performed well in the 100kg series of tests. It caught the test mass with a max arresting force ranging from 6.12-6.8kN with a system extension from 185-229mm. It did not damage the rope and was releasable after each drop. The GriGri was noticeably easier to release than the MadRock Lifeguard. The rope experienced some ‘fuzzing’ where it passed through the device.

In the 200kg test series the Petzl GriGri experienced structural failures. The pin holding the two halves of the shell bent on each test causing the cam and handle to not return to its ‘sprung’ position. We stopped this series after 2 iterations because of the consistent damage to the device, and the fact that the device is not rated for a 200kg load.

Black Diamond ATC Guide on 9.5mm Rope

The Black Diamond ATC Guide is a stitch plate/plaquette device rated for rope sizes from 8.1-11mm. Per Black Diamond, when used for a single rope, the ATC Guide is for rope diameters from 8.9mm and 11mm and the ATC Guide Alpine is for diameters from 8.5mm to 9mm while recognizing a .2mm tolerance for manufacturer variability in measurement and reporting of rope diameter. It should be noted that in the 2021 test series the 8mm rope was below specification on the ATC Guide Alpine and in 2023 the 9.5mm rope was within specification for the ATC guide. Depending on how it is reeved relative to the molded ‘teeth’, there is a high friction mode (HFM) and regular l friction mode(RFM). We explored both modes with our test series:

- In the 100 kg mass test series, high friction mode was able to stop the load easily with a max arresting force of 3.36-4.01kN with a system extension of 467-556mm. Low friction mode produced results with a max arresting force of 2.46-2.58, and system extension of 978-1116mm. 3 of the 5 low friction mode tests resulted in system extensions greater than 1000mm.

- In the 200 kg mass test series, high friction mode stopped the load with a max arrest force of 2.56-3.3kN with a system extension from 1376-2525mm. All the test system extensions were greater than 1000mm.

Recall that the ASTM standard requires a 50N ‘Mechanical Hand’ to hold the standing end of the rope for the test. The BD ATC Guide fails this criteria throughout the tests. The operator notes that in all test masses and all configurations if the ATC is not operated using correct brake hand technique all the test masses would have gone to the ground. The BD ATC Guide requires a competent belay operator.

Münter on 9.5mm Rope

The 100kg test series we used a münter hitch on an Omega HMS carabiner. All the münter/super münter tests were operated in both one-handed (holding on to the standing end) and two-handed (NCRC-style holding both strands with both hands).

The münter was able to catch the 100kg load with a max arrest force of 2.5-3.52kN and a system extension of 487-1129 mm. One test in the series, using one-handed operation, exceeded the 1000mm system extension limit. Some aluminum transfer was observed on the rope in all tests.

The super münter was able to catch the 100kg load with a max arrest force of 3.36-6.2kN and a system extension of 145-477mm. The super münter was able to catch the 200kg load with a max arrest force from 3.16-8.06kN and a system extension of 329-676mm. The super münter clearly shows the relationship between MAF and system extension with a correlation of high peak forces on short system extensions.

The münter/super münter also needs more than 50N ‘hand’ to control its function. They both require a competent operator.

Hitch Testing on 9.5 Rope

For this series of tests (Table 11) we used a Bluewater 8mm VT Prusik eye to eye cord, tied by the same practitioner throughout.

Table 11: Hitch Testing on 9.5mm Sterling CanyonTech/Tactical Response Rope

| Hitch | Mass (kg) | N | System Extension (mm) Max / Min /Avg | Arrest Force (kN) Max / Min / Avg | |||||

| Valdotain Tresse | 100 | 5 | 323 | 182 | 217 | 5.94 | 4.20 | 5.36 | |

| 200 | 5 | 1993 | 513 | 980 | 8.30 | 3.78 | 5.57 | c | |

| Schwabisch (Max/1) | 100 | 5 | 153 | 145 | 148 | 6.50 | 6.06 | 6.24 | |

| 200 | 5 | 1096 | 254 | 605 | 9.78 | 5.48 | 7.53 | ||

| Distel | 100 | 5 | 161 | 140 | 148 | 6.38 | 5.94 | 6.17 | |

(c) 2 of the 5 tests went to the ground.

Out of the 25 tests performed on the Bluewater 8mm VT Cord tied in various hitches, only one was releasable; this test was tied with a Valdotain Tresse. The test had a max arrest force of 4.72kN and a system extension of 1993mm. Of the 200kg tests tied with a Valdotain Tresse; two of drops went to the ground and the VT Cords had a burn through the sheath rendering them unusable. Another test exceeded the maximum system extension at 1993mm. While another exceeded the max arrest force at 8.3kN. Only one of the Valdotain Tresse hitch tests was within limits (although not releasable).

None of the 25 test drops in either 100 kg or 200 kg masses damaged the rope. On many of the tests the VT Cord became ‘adhered’ to the rope. Not in the sense that the cord and the rope melted into each other, but that it took effort to unwrap the cord from the rope. A sound similar to pulling apart Velcro was noted.

The results did not show much difference in performance between the Schabisch and Distel hitches at 100kg. Both hitches essentially perform the same.

Testing Systems

Following the series of component testing it became apparent that the only viable system to test was the combination of ATC Guide and Scwabisch hitch. The

elimination of other systems or devices was based on:

- Preference that the resulting system has an auto-stop. ASTM and NFPA tests do not require a hands off “whistle stop” condition. The requirement for a 50N mechanical hand implies constant operator control of the rope tail behind the device.

- The system should be operable by one person per rope. This requirement could be eliminated if the system were operated in a “shark fin” configuration with one operator on the handles and tails and one operator minding both hitches . We recognize that while it takes three hands to operate a handled device and hitch, parallel systems can be operated with 4, not 6 hands. However such a setup requires a specific anchor configuration and workspace that may not always be possible.

Considering the second criteria above and test failures at 200kg, the Madrock Safeguard and Petzl Grigri were not considered for systems testing. Given criteria 1 and 2 above, the munter hitch was not considered for systems testing. This choice should not be considered an opinion that the munter is an unacceptable belay device. The Schwabisch hitch was chosen both because of performance in testing and simplicity of the hitch configuration

The configuration chosen was to put the Schwabisch Hitch in front of the ATC, instead of behind. Many TTRS systems incorporate a hitch behind the descent control device (DCD) as it had been tested extensively in the EMBC rope Rescue New Initiatives Fund Equipment Testing Summary Report, and its use outlined in the Emergency Management BC Wildland Rope Rescue Field Guide (EMBC, 2018) and elsewhere.

However, between the numerous operational advantages to having the hitch in front of the DCD and the use of high-modulus aramid materials, we could develop a strong case for implementing the hitch in front of the DCD. The use of asymmetrical prusiks, sewn eye to eye prusiks also contribute to this chosen configuration. We have also seen the Valdotain Tresse Prusik tested like this before. Mike Gibbs of Rigging for Rescue tested VT prusiks as rescue belays in a

2014 ITRS presentation, as well as in high modulus aramid fiber friction hitches in technical rope rescue systems, also presented at ITRS in 2014.

Gibbs stated “We have conducted many tests with the VT as a belay system fall arrest device and it has performed very reliably in drop testing. We have also conducted numerous tests with human operators. Some have included the VT on the standing end of the DCD in dual tension and some on the running end. We have not observed any substantive differences in fall arrest performance between the two locations. In the end, we agree that the VT on the standing end offers numerous advantages for operational considerations.

And absent compelling evidence that would suggest one location is “safer” or more reliable in fall arrest than another, we favor the standing end for the operational benefits.” Gibbs (2019)

Table 12: System on 9.5mm Canyon Tech / Tactical Response Rope using 200kg Mass

| System | N | System Extension (mm) Max / Min / Avg | Max Arrest Force (kN) Max / Min / Avg | Notes | ||||

| ATC Guide High Friction Mode / Schwabisch Hitch | 5 | 623 | 519 | 578 | 6.94 | 6.10 | 6.64 | None of the drops were releasable |

“Don’t go get all the lightest things, find the things that work, that you need, and make them as light as you can.”

-Mike Maurer, Gossamer Gear, Deschutes County Mountain Rescue

Conclusions

Currently there are 8mm and 9.5mm rope rescue systems deployed by various teams. Collectively our understanding on how these systems perform in a true dynamic rescue environment cannot be compared to that of larger diameter rope systems. As diameter decreases any variable in the system can be magnified and impact performance. Observed variables include rope and hitch cord material and construction, device tolerances, hitch configuration, and method of operation. Other variables such as temperature, moisture, and component wear will impact performance as well. In smaller diameter systems it is imperative that specific combinations of components and methods of use be understood.

General

- The ‘Man/Machine Interface’ becomes a real factor with 8mm ropes. They are harder to hold and control, especially with gloves hands. Petzl cautions users about smaller diameter ropes: “Thin ropes require special precautions during use because they are more difficult for the hand to grip. They can be more difficult to control while descending or in the event of a fall. The use of thin ropes requires greater vigilance and a high level of experience with belay techniques”. (Petzl, 2023) All of our testing was done in a controlled, warm, dry environment. The competent operator did everything they could to control the rope on all the tests. Working in wet, snowy, cold environments would certainly challenge the operator’s to have full control of the rope. As rope diameters decrease the interfaces between rope/device/hitch/human all become less tolerant of variables.

- The Schwabisch and Distel Hitch would be our ties of choice over the Valdotain Tresse.

The Valdotain Tresse hitch failed to arrest the load several times and is much more difficult to tie and inspect. For the purposes of system belays we find no benefit to the Valdotain Tresse hitch.

- Our testing only used Bluewater VT cords. We cannot speak to the expected performance of other eye to eye cords as the materials and construction vary. Further, we noted several instances where the system performance relied upon a specific combination of materials and construction in both the rope and hitch cord.

- In regards to the Scarab, or any similar bar or horned style devices, its ability to pass these tests was dependent on the operator. Understanding, and adjusting for friction to have the right number of horns becomes an important variable. The number of bars or horns that is ideal for controlling a load, may not be the number of bars or horns that would result in suitable belay catch.

- Is the 15kN MAF prescribed in BCCTR BCDTM and NFPA an appropriate measure of success given the potential injurious consequences to a rescuer or patient? The technical rescue community should consider a lower threshold more in line with fall protection standards.

- Complete systems should be evaluated in their manner of use. The performance of the system defines success rather than isolated performance of individual components within the system.

Specific to 8mm Rope Systems

- 8mm rope systems are not the best for teams with stratified experience. Operator error and improper rigging were the main causes of 78% of the adverse shock loading events by mountain rescue teams (Smith, 2021). 8mm rope systems have difficulty absorbing shock energy imparted by rescue size loads. Margins are pretty thin, teams should understand where shock loads can be introduced to systems and be able to mitigate them.

- A 0.33 factor fall on 8mm rope using the Mad Rock Safeguard has a high potential for rope failure. The 100kg drop test mirrors the practice of using a cammed device on a work restriction or edge line. We cannot recommend the use of this system for work restriction or rappelling over an edge with a potential for a 0.33 or greater fall factor.

- The difference in construction between 8mm ropes sheaths made mostly of Technora (Bluewater Canyon Extreme) and a mix of Technora/Polyester (Sterling Canyon Lux) significantly affects the performance of the rope when catching falling loads. Ropes with a higher polyester content in the sheath experience melting that affects the continued serviceability of the rope as well as the gripping ability of aramid friction hitches.

- Current offerings of 8mm rope range from 24-27kN MBS. Practitioners planning on employing a smaller diameter rope must revisit their system strength factors, as it is hard to meet historical standards such as 10:1 or even tighter standards of 4:1 with smaller diameter rope.

Specific to 9.5mm Rope Systems

- A properly operated system of technora sheath 9.5mm rope, using 8mm Bluewater VT cord, and ATC Guide is a safe and reliable system especially when operated as a mirrored TTRS. Operators can be trained quickly with low complexity using basic rope skills.

- Rope systems continue to evolve and with the use of high modulus fiber eye to eye hitch cords, placing friction devices in series such as Parallel Plaquettes is no longer necessary for belay competency on 9.5mm rope.

- 9.5 mm systems are more forgiving of operator nuance and friction hitch performance.

The margins for success are wider and more appropriate for teams of stratified skill.

Future Directions

- A deeper dive into the max arrest forces the industry uses as a standard is warranted. It would be beneficial to define the criteria for the forces seen by a rescuer, or multiple rescuers, in the event of a fall.

- There is a relationship between knot setting and MAF. This relationship deserves further exploration to determine if there is a predictable and useful force dissipation effect in rescue systems. Previous testing on caver cowstails supports this relationship. (Chamonix, 2006)

- The rope rescue community should take a hard look at the appropriateness of BCCTR BCDTM style testing for dual main systems. It continues to be the touch stone with which all drop testing is referenced. As the rope rescue community creates better practices to mitigate an actual 0.33 fall factor, and as smaller diameter rope pushes the margins of system strength factors, can a different test standard better define the situation?

- Comparison testing of other eye to eye cords on various ropes would be interesting.

Glossary

- Anvil Effect – Metal on metal contact of cam and braking surface in a handled descent control device

- ASTM – ASTM International, formerly American Society for Testing and Materials

- BCDTM – Belay Competency Drop Test Method

- BCCTR – British Columbia Council of Technical Rescue

- GN – Load to Ground

- MAF – Maximum Arrest Force

- MBS – Minimum Breaking Strength

- NFPA – National Fire Protection Association

- TTRS – Twin Tension Rope Systems

Acknowledgements and Gratitude

- 351st Special Warfare Training Squadron, Kirtland AFB, Albuquerque NM

- Bluewater Ropes, Mark and Scott Newell

- Sterling Ropes, Matt Hunt

- Petzl NA, Steve Petty and Bill Moore

- CMC Rescue

- Skanska USA Civil

- Conejo Powder Resort, Durango CO

- Mike Gibbs and Kevin Koprek, Rigging for Rescue

- Richard Delaney, Rope Lab

References

- Ashley, C.W. (1956, January 1). The Ashley Book of Knots.

- ASTM Standard F2436-14(2019), “Standard Test Method for Measuring the Performance of Synthetic Rope Rescue Belay Systems Using a Drop Test” ASTM International, West Conshohocken, PA, 2019, DOI: 10.1520/F2436-14R19, www.astm.org

- Black Diamond (2018), Technical Guide, ATC Guide ATC-Alpine Guide Rappel/Belay Device, Salt LAke City UT, USA, Accessed 2021

- Carlson, Rich, Owner, Canyons and Crags, Personal Communication, January 2023

- Code of Federal Regulations (n.d.) 1910.140(d) https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.140

- Conterra, Technical Guide, Scarab Rescue Tool, Bellingham WA, USA, Accessed 2021

- Crandall, Steve, (2012) RESCUE Rope Based Rigging Concepts, Heavy Rescue Training LLC, Salt Lake City, UT, USA

- Delaney, RIchard, Ower, RopeLab, Koatoomba, New South Wales, Australia , Personal Communication 2019-2023

- Gibbs, Mike (2019), VT Prusik For Rescue Belay, International Technical Rescue Symposium, Albuquerque NM, USA

- Gibbs, Mike, Owner, Rigging for Rescue, Ouray CO, Email Communication, Oct 2020

- Gibbs, Mike, Owner, Rigging for Rescue, Ouray CO, Personal Communication, May 2022

- Larson, Arnör (1991), Belay competence Drop Test Method, British Columbia Council of

- Technical RescueSanta Fe Springs, CA, USA, Accessed 2021

- Hunt, Matt, Director: Fire, Rescue, Tactical Sales, Sterling Rope, Greensboro NC, USA, Personal Communication, 2023

- Koprek, Kevin, Instructor, Rigging for Rescue, Ouray CO, Personal Communication, 2023 “Material Properties – Marlow Ropes Inc.” Marlow Ropes Inc, https://www.facebook.com/marlowropes/, https://www.marlowropes.com/us/innovation/material-properties/. Accessed 17 Sept 2023

- Mauther, Kirk (2017), Emergency Management British Columbia (EMBC) Rope Rescue

- New Initiatives Fund (NIF) Equipment Testing Summary Report.

- Maurer, Mike (2015) Gossamer Gear, Deschutes County Mountain Rescue, WA, Personnel communication

- Nelson Sports Inc., DBA Mad Rock (2008), Technical Guide Safeguard RappelBelay device, Santa Fe Springs CA, USA, Accessed 2021

- NFPA 2500:Standard for Operations and Training for Technical Search and Rescue Incidents and Life Safety Rope and Equipment for Emergency Services, 2022 Edition.

- NI0SH CFR 29, Subtitle B, Chapter XVII, Part 1926, Subpart M, §1926.502(d).16.ii (2019) Fall protection systems criteria and practices.

- Petzl (2023),GriGri Technical Notice D0015500H – D0015400D (070921), Crolles, France

- Prattley, G. (2021, August 30). Canyon Rope Rescue Testing. Over the Edge Rescue. https://overtheedgerescue.com/canyoning/canyon-rescue-testing/

- Smith, Gordon (2021) 60 years of Experience Shock Loading of Rescue Rigging Systems: Is it Time for New Criteria for What Systems Need to Hold? International Technical Rescue Symposium, Denver CO, USA

- Spain, Justin (2019) Rescue Systems at 9mm, Presentation, International Technical Rescue

- Symposium, Albuquerque NM, USA

- Rigid Lifelines (2013), The History of Maximum Arresting Force. https://www.rigidlifelines.com/blog/the-history-of-maximum-arresting-force/