Evaluating Rescue Knot Efficiency in 11 mm General Use Ropes

Motivated by mounting questions about the strength and characteristics of 11 mm NFPA General Use Rope, CMC School Instructors, LeRoy Harbach and John McKently, began a series of tests in the CMC lab. Their exploration into knot efficiency involved 487 tests across a number of rope types, revealing insights into how diameter, construction, and materials impact knot efficiency. They also expanded the scope of their study to evaluate smaller diameter ropes being proposed for rescue systems and generated guidelines for estimating knot efficiency based on rope diameter. Harbach and McKently presented these results at the 2023 ITRS conference in St. Louis, MO in their presentation titled “Rescue Knot Efficiency Revisited, Again”. Below is a copy of their presentation, which you can also find on the ITRS website (itrsonline.org), along with papers from the other conference presenters.

About ITRS

CMC proudly serves as a co-founder and co-sponsor of the renowned International Technical Rescue Symposium (ITRS), an annual gathering that brings together a diverse community of professionals specializing in fire, mountain, cave, urban, industrial, and swift water rescue. During the symposium, presenters generously offer their own research findings, testing outcomes, and field experiences for the collective benefit, encouraging everyone to contemplate and implement these insights. The symposium’s scale creates an optimal environment for discussion and knowledge sharing.

Case Study: Rescue Knot Efficiencies Revisited, Again

(ITRS 2023)

LeRoy Harbach and John McKently, CMC Rescue School

Introduction

This presentation, as you can tell from the title, is a follow up to our earlier presentations in 2008 and 2014 at ITRS about knot efficiency for various sizes of kernmantle rescue rope.

With the wider acceptance of G rated 11mm ropes we have been getting questions from students in our classes about the knot efficiency using that rope and other smaller, meaning less than 12.5 mm (½”) diameter, ropes for rescue. Our previous testing was all done on what at that time was NFPA “G” rated rope nominally 12.5 mm in diameter.

We thought it would be simple. Run the tests with the new rope on the same knots, and be done with it. It didn’t turn out that way as you will see.

For reference this table is a summary of the results of our previous testing.

| Knot | Rhino Rescue – 1987 | Nylon Lifeline-2008 | Polyester Lifeline-2014 |

| Bowline | 67% | 75% | 58% |

| Butterfly End to End | 66% | 60% | |

| Butterfly Loop to End | 75% | 77% | 61% |

| Figure 8 End to End | 74% | 54% | |

| Figure 8 Loop to End | 80% | 77% | 70% |

| Double Loop Figure 8 | 82% | 75% | 66% |

| Figure 8 Bend | 81% | 57% | 66% |

| Double Fisherman | 79% | 79% | 80% |

| Inline 8 End to End | 51% | 49% | |

| Inline 8 Loop to End | 75% | 73% | 63% |

| Scaffold Knot | 81% | 69% |

Notes on the table above

- The above tests were all conducted on 12.5mm (1/2”) samples

- Cordage Institute CI-1800 test method (4” drums, 38-150mm/Minute pull rate etc.)

- At least 5 samples for each knot in the Lifeline tests. Unknown for the 1987 tests.

- Results were calculated by dividing the results of control samples (no knot) tests into the knot tests.

General Notes and Disclaimers

The data gathered over 15 years is incomplete and probably inconsistent, Different test machines and reporting methods were used. In the case of the 1987 data no information about the test method is available and it was before the current test methods were written or electronic load cells were used.

No one type of rope was sampled over the entire diameter range.

For the end-to-end tests with midline Figure 8, Butterfly and Inline 8 knots no load was applied to the loop. That might not be a real-world condition, but all knots were tested the same way for comparison. A carabiner was placed in the loop to ensure that the loop did not collapse when force was applied.

Not all the knots were tied by the same person and while all were pulled to be “hand tight” that might vary. It is unknown if that is a factor for knot strength.

Because we had a mix of different ropes, in different sizes from different manufacturers we were limited in our ability to run a complete set of 5 tests each on the 12 knots. Therefore, we scrapped our original plan and are reporting different comparisons based upon rope diameter, construction and materials. Our intent is to do further testing, including repeating the 2008 and 2014 tests to have a more complete data set. What follows is the result of 487 tests.

- The ropes were divided into 5 Categories:

- 9.5mm Polyester Sheath (KMIII)

- 9.5mm Aramid Sheath (Canyontech and Tac Response)

- 11mm T Polyester sheath (KMIII and Static Pro)

- 11mm G Polyester sheath/Nylon core (G-11 2.0 and SYNC)

- 9.5mm (Static Pro)

- Not using Lifeline – No other nylon sheathed rope to compare to

- Only comparing knots with full data set

- Alpine Butterfly – End to End

- Alpine Butterfly – Loop to End

- Bowline

- Double Fisherman

- Double Loop Figure 8

- Figure 8 Bend

- Figure 8 Loop

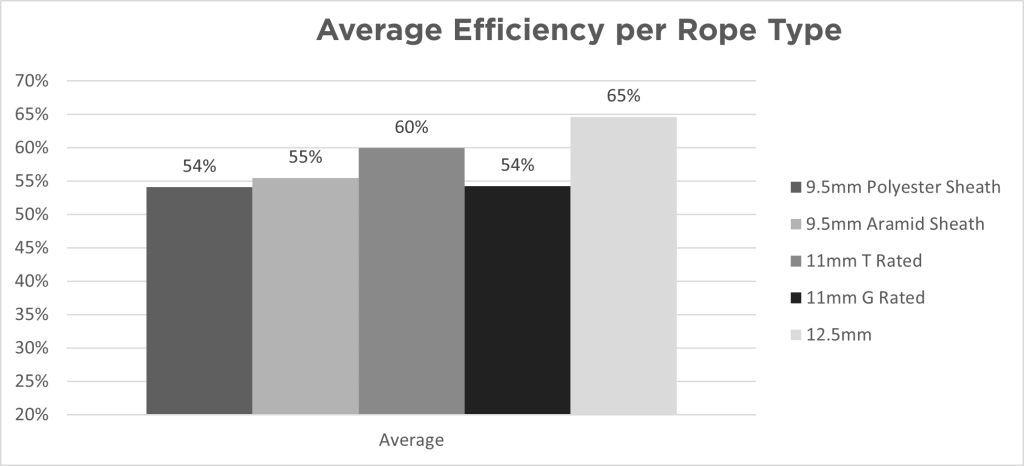

- With data cleanup, clear trend between 9.5, 11, 13mm ropes (poly sheaths).

- 54% vs. 60 % vs. 65% respectively.

- Larger diameter= larger bends= higher efficiency

- Aramid sheath ropes performed similar to poly sheath ropes on average.

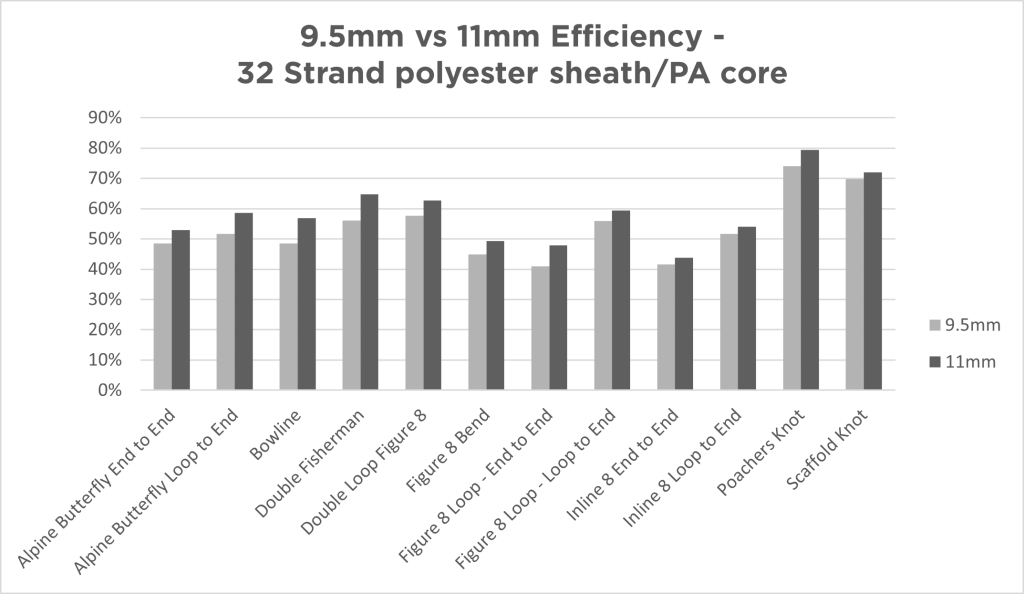

Diameter Comparisons

9.5mm vs. 11mm

- Comparing 32 strand polyester sheath/PA core across diameters (KM III).

- Complete knot set.

- Larger diameter had higher residual strength across the knot range.

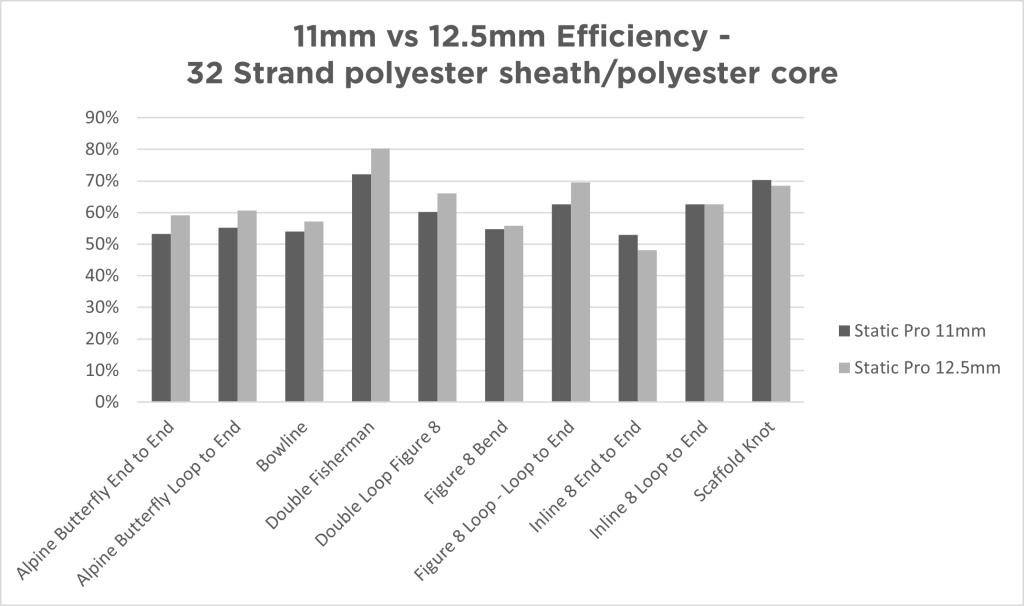

11mm vs. 12.5mm

- Comparing 32 strand polyester sheath/polyester core (Static Pro).

- Missing Fig 8 End to end, Poachers knot

- Larger diameter generally performed slightly better.

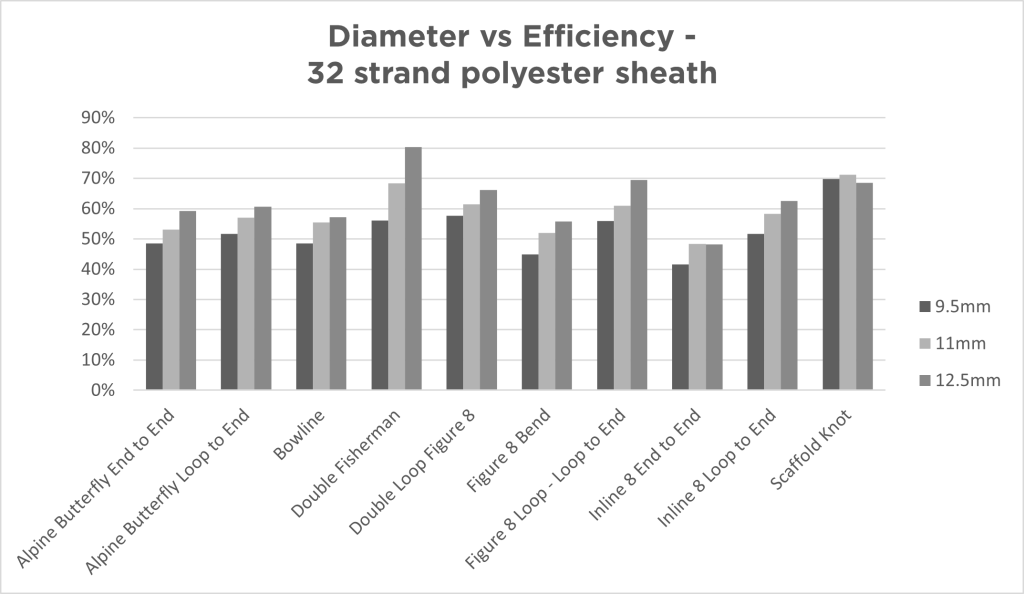

9.5 vs. 11mm vs. 12.5mm

- Comparing KMIII, Average of 11mm Static Pro and 11mm KMIII, 12.5mm Static Pro.

- Different cores, similar 32 strand poly sheath. We suspect sheath construction influences efficiency based on 11mm g rated rope testing.

- Missing Figure 8 loop end to end, poachers knot.

- Consistent pattern of increasing efficiency as diameter increases.

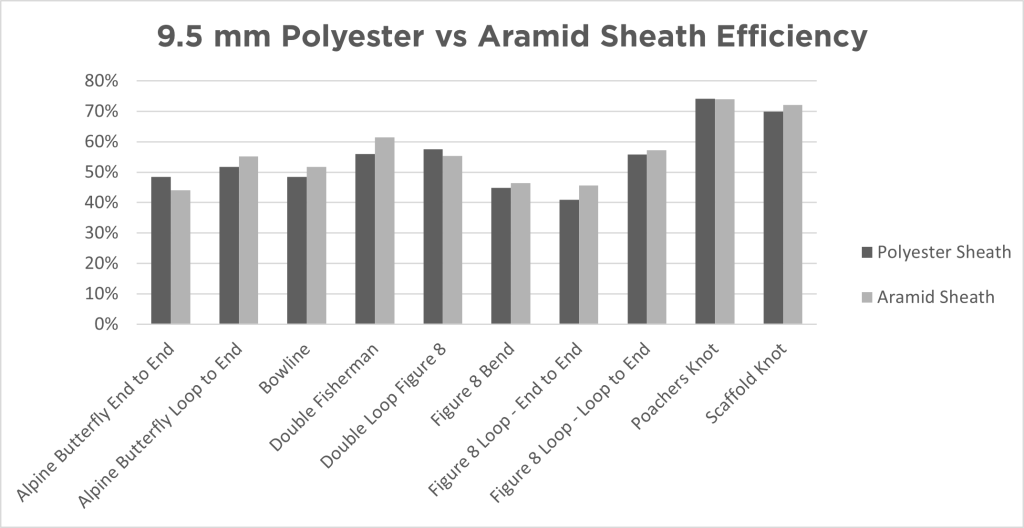

9.5mm Aramid vs. Polyester Sheath

- Missing Inline 8 data (both)

- KMIII vs. average of Canyon tech and tactical response

- Performance was similar across both constructions.

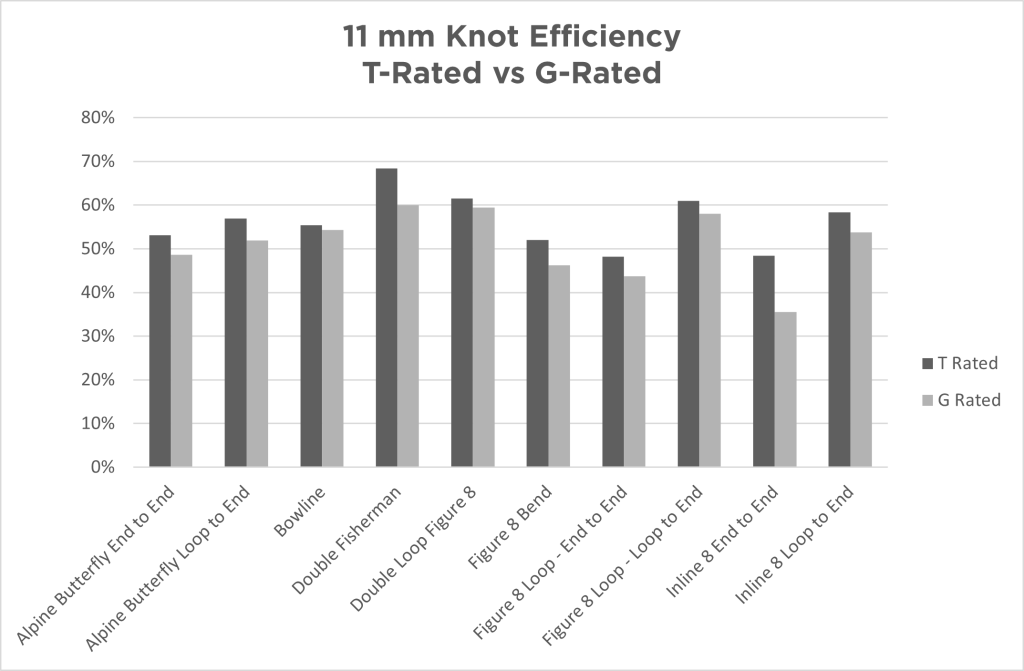

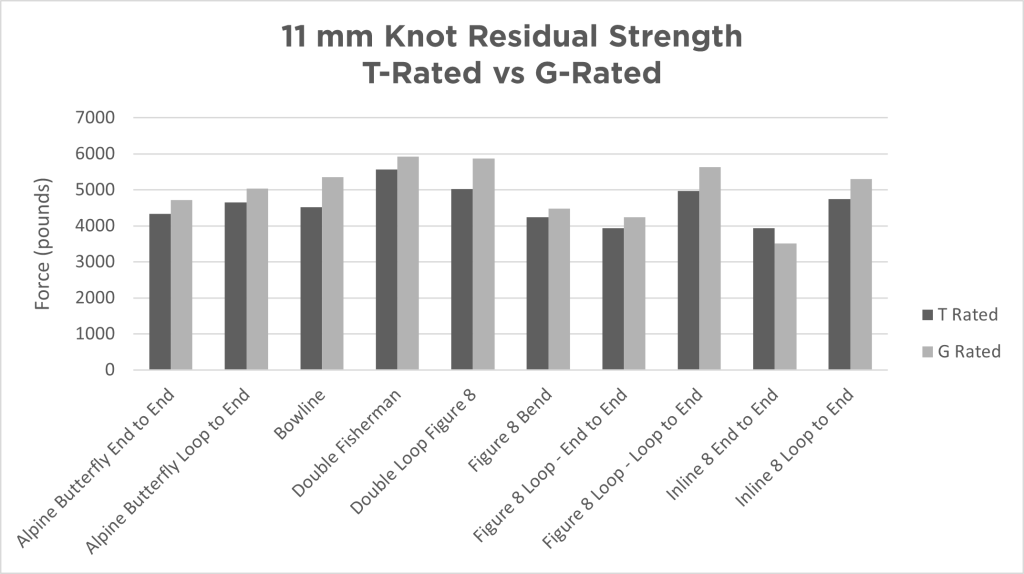

Traditional 11mm vs. G rated 11mm

- T rated: KMIII and Static Pro, G Rated: G-11 2.0 and SYNC

- Missing Poachers and Scaffold knots. G-11 data not following trends, likely testing differences vs. other ropes.

- Partial set of SYNC data.

- Showing both efficiency and residual strength

- Even though lower %, average breaking strength is higher.

- Explain the changes in construction – more core less sheath.

Conclusions

Based upon this testing you might want to consider using a lower knot efficiency when doing system safety factor calculations. We are recommending 50% until further testing proves otherwise.

As stated earlier it is our intention to continue this project by repeating the tests done in 2008 and 2014 and by including additional rope types and knots as we received sample material from other manufacturers.

Acknowledgements

The authors are very grateful for the assistance and encouragement of the CMC Engineering staff led by Tyler Mayer. We especially want to thank Conner Warren for making sense of the test results and for creating the graphs included in this paper.

We would also like to thank Matt Hunt from Sterling Rope, Loui McCurley from PMI, and the management of CMC Rescue for providing rope samples for testing.