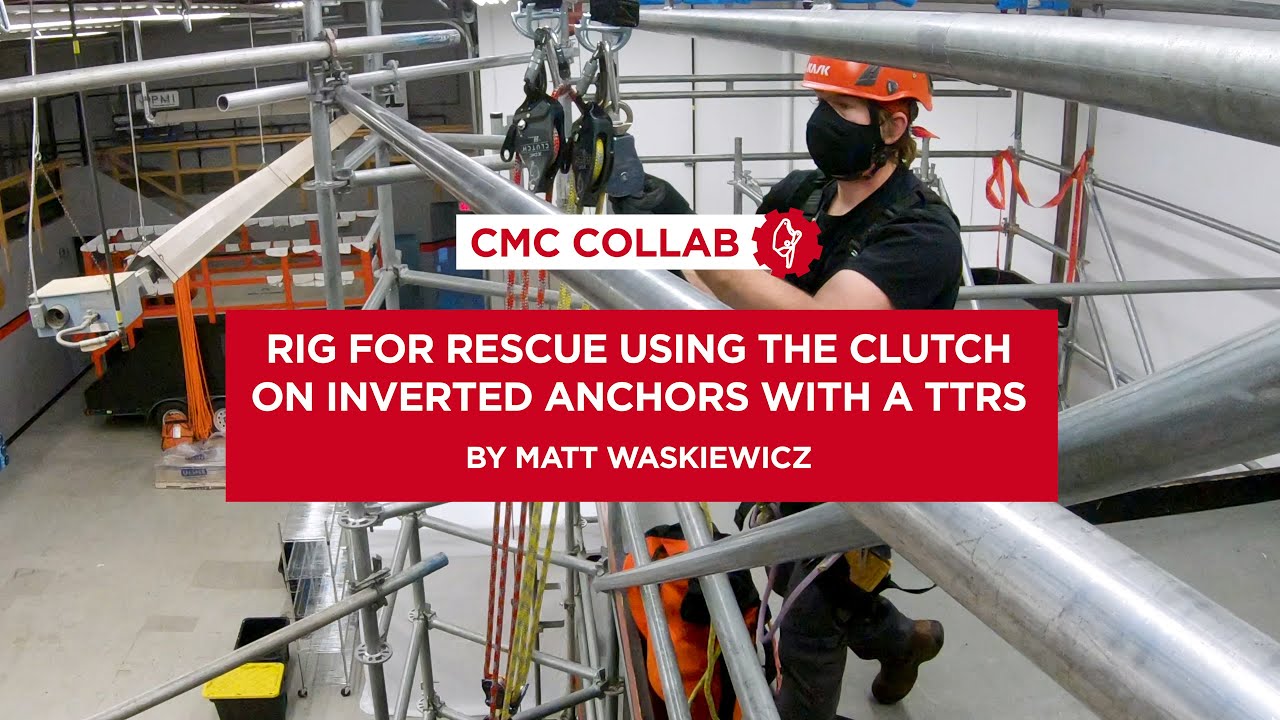

Rig for Rescue Using the CLUTCH on Inverted Anchors with a TTRS - CMC Collab by Matthew Waskiewicz

We’re excited to post this video collaboration with SPRAT and IRATA Instructor Matthew Waskiewicz. Matthew explains how the CMC CLUTCH™ BY HARKEN INDUSTRIAL™ excels as a highly-efficient, multi-purpose tool for rope access technicians. By rigging the CLUTCH for rescue on inverted anchors in a Twin Tension Rope System (TTRS), the technician is able to smoothly perform the remote operation of an incapacitated worker. This allows a potential rescue to be conducted without intervention. Click here to read more about Matt and his testimonial on the CLUTCH. A full transcript is provided below.

Full Transcript:

The CMC CLUTCH by Harken Ind. is an excellent tool for use in a Twin Tension Rope System (TTRS). A TTRS can be considered when a hauling and lowering system is suitable for the job and scope of work. In this example the TTRS is utilized for the remote operation of a worker. This allows a potential rescue to be conducted without intervention.

When using a system to haul or lower considerations for your risk assessment should include:

1) The availability and strength of the anchors.

2) The management of personnel working near an edge

3) The path of the ropes are free from hazards.

After a full Risk Assessment is carried out, we begin our hauling operation. First we lock off both of the Clutch’s, and have the technician commit to the system.

Next we install a rope grab on the Twin Tension Rope System, and add a pulley to create mechanical advantage.

And finally we add a redirect to allow the hauling system to be pulled downwards. This allows the technician to use their body as a counterweight to the load.

In this case a firm grip on both ropes with gloved hands, pulling on a redirected 3:1 is able to pull the load up with manageable effort.

As the rope grab gets near the anchors, a simple adjustment sliding the grab towards the load resets the system.

Now we’ll turn the haul to a lower, removing the mechanical advantage, and redirecting both ropes through carabiners on the anchor. This will help manage the rope along the Clutch’s Friction Shoe.

We operate both of the Clutch handles simultaneously, maintaining control of both ropes with the other hand. It is important to lower slow and precise.

A nice smooth lower enables the technician to maintain stability along the structure.

Here we have the technician ascending a system pre – rigged to lower with dual CLUTCH’s at the ground anchors and redirect anchors above the technician.

If the technician were to become incapacitated, a simple lower is all that is required for rescue.

Here we are able to operate both Clutch handles at once with the other hand maintaining control of both ropes to ensure contact with the Clutch’s Friction Shoe.

Contributing factors to variability in the system will include

- The total length of ropes

- Wear in the soft or hard goods

- The build up of water, dirt or ice

- The total mass of the load.

Continuous training in these types of techniques is required to be able to adapt during changing situations.